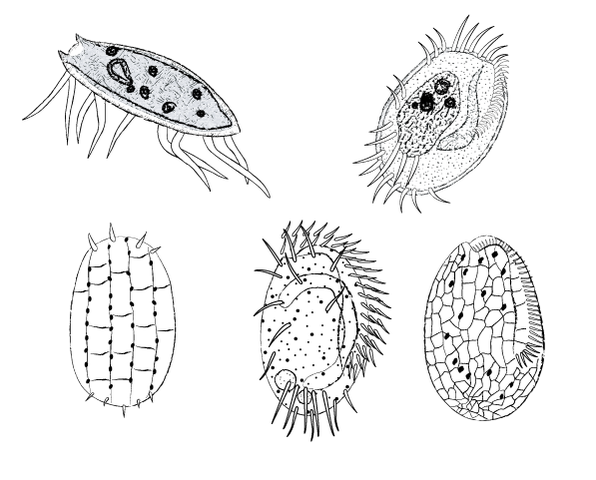

Free swimming and crawling ciliates common in healthy wastewater systems

Free swimming and crawling ciliates common in healthy wastewater systems - Note floc size, density, and filaments - compare to "normal" system levels (100x)

- Free bacteria and pin floc (best seen at 400x)

- Now look for indicator protozoa (amoeba, flagellates, ciliates, and stalk ciliates)

- Any higher life forms such as rotifers or worms

- Finally, anything unusual or big changes from previous exam

RSS Feed

RSS Feed