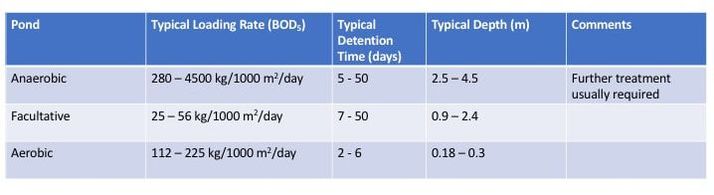

Key parameters for lagoon treatment are loading rates per unit surface area. Surface area is important for oxygen diffusion and algae growth. Much like constructed wetlands design, the natural biological decay processes are important for effluent quality. Below are the general design guidelines from Curi & Eckenfelder (1980).

|

The earliest wastewater treatment facilities consisted of lagoons with no mixing and dissolved oxygen provided by surface diffusion/wave action and algae growth. While they take up much more space than more advanced treatment systems, lagoons/ponds do not have high operational costs and are often the best choice for remote locations or areas where there is not treatment alternative.

Key parameters for lagoon treatment are loading rates per unit surface area. Surface area is important for oxygen diffusion and algae growth. Much like constructed wetlands design, the natural biological decay processes are important for effluent quality. Below are the general design guidelines from Curi & Eckenfelder (1980). Step-Feeding influent - the why and when to use multiple inlets for adding influent wastewater11/19/2017

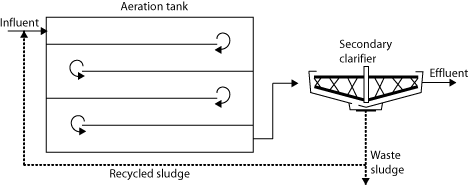

Plug-flow or near plug flow wastewater systems have proven effective for treating both BOD/COD and nutrients including N & P. In a true plug flow system, the influent moves through the system in one direction, much like water in a pipe. Systems with a rectangular basin with length over 4x the width often resemble an "imperfect" plug flow system - where flow approximates a true plug flow system. While effective for treating wastewater, a plug flow system is subject to problems related to:

To monitor step feed effectiveness, look at D.O. profiles along the basin length. Aim for consistent D.O. residuals along the first 50% of the basin. We want 80% of the soluble BOD removal to occur in the first part of the basin if we also need to remove ammonia nitrogen. For optimal ammonia oxidation, you need to have at least a 2 mg/L D.O. residual in the ammonia removal zone. To use step-feed effectively, operators must run DO residuals and oxygen uptake rates at multiple points. Use microscopic exam and SV30 tests to closely monitor filamentous organisms. By using good monitoring, step-feed can help with systems that often experience bulking. Extended aeration biological treatment systems operate at a lower F/M than the original activated sludge designs. Why did we move to extended aeration over other aerobic treatment systems?

While operating in extended aeration mode has a lot of upside, running a system at too low an F/M ratio can be counter productive and effluent quality can decline. As you move further into endogenous respiration (very low F/M) the following things happen:

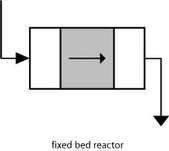

Anaerobic waste pretreatment extends back to the earliest Imhoff and septic tank waste treatment systems. While these early systems were passive with no mixing or biosolids recycling, they biochemically operate in the same manner as the latest in fluidized bed anaerobic reactors. Unlike digesters where methane production and solids stabilization is the primary goal, anaerobic pretreatment is concerned with hydrolysis of complex molecules converting the complex and insoluble organics into short chain volatile fatty acids (VFA). The conversion into VFA does reduce BOD/COD concentration via creation and maintenance of microbial cells. If the anaerobic pretreatment system produces methane - from the growth of methanogens on VFA - the BOD/COD reduction is much greater than a system with no methanogen activity. We see anaerobic pretreatment with high strength wastewater that would be difficult and cost prohibitive to treat in a standard aerobic system - maintaining D.O. would require a massive amount of energy. One common application of anaerobic pretreatment is in meat processing wastewater. Often these systems have an anaerobic basin with a grease cap or physical cover following DAF or other pretreatment system. The anaerobic basin microbes grow on soluble organics and via anaerobic biochemistry begin to reduce the carbon chain length making insoluble fatty acids more soluble. This is a much slower process under anaerobic conditions than in an aerobic system resulting in the "grease cap". With a relatively long residence time, the anaerobic pretreatment removes a substantial portion of influent BOD and converts proteins into ammonia which is amenable to rapid treatment in the following activated sludge unit. While meat processing is a common application of anaerobic pretreatment, it is also useful in many waste streams with long chain organic compounds that require solubilization to become BOD5. Examples include cellulose, fats, and large particulate material. |

AuthorErik Rumbaugh has been involved in biological waste treatment for over 20 years. He has worked with industrial and municipal wastewater facilities to ensure optimal performance of their treatment systems. He is a founder of Aster Bio (www.asterbio.com) specializing in biological waste treatment. Click to set custom HTML

Archives

April 2024

|

RSS Feed

RSS Feed