- Find out why you lost nitrification. A previously stable nitrifier population, just doesn't get up and leave. You had a gradual loss of nitrifiers in the system or some type of shock that caused a rapid drop in populations. Find out what happened and then evaluate control options.

- Run influent Total Nitrogen (TKN), ammonia, amines to discover how much nitrogen is entering that needs to be oxidized.

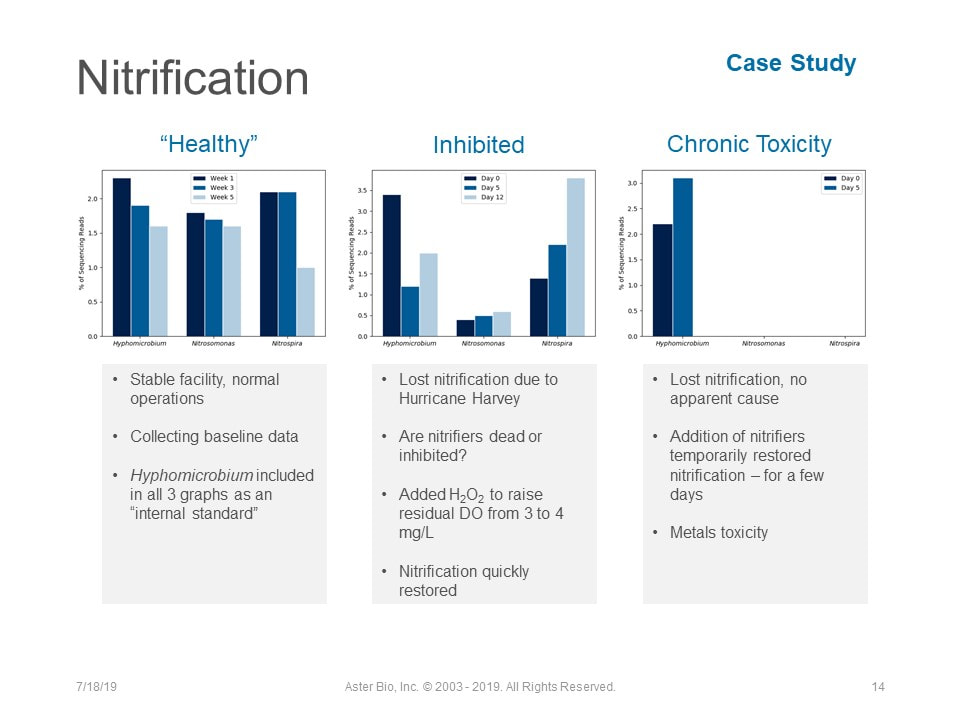

- If you have a history of nitrifier loss, you can use qPCR and MCA to track AOB/NOB populations. Molecular testing will show population changes well before effluent ammonia increases. I have found molecular testing effective in adjusting MCRT, F/M, and identifying chronic toxicity to nitrifiers.

- Run an acute nitrifier toxicity test if you cannot find reasons for the loss in activity or suspect influent inhibition. Acute testing involves using a concentrated nitrifier culture in a 2 - 3 hour test to determine % inhibition of AOB activity.

- After you correct the situation and get an environment suitable for nitrifier growth, they will eventually grow back to needed levels. However, this can take longer than is acceptable. Nitrifier recovery time can be reduced by adding commercial nitrifiers. These nitrifier concentrates require refrigeration and have a very short-shelf life, so consider logistics when preparing to use the cultures. Also, make sure that you have the system in the best shape possible for promoting nitrifier growth.

|

Among the slowest growing organisms in your wastewater treatment plant, nitrifiers (AOB/NOB) are also picky about pH, dissolved oxygen, and inhibited by many compounds often present in wastewater. Since you need nitrifiers to efficiently remove ammonia and nitrite above the amount used by cells for growth on influent organics, keeping a stable nitrifier population is often a challenge. So what should you do when effluent ammonia increases - indicating a loss of nitrifeir activity? Instead of immediately reaching for a commercial nitrifier product , I suggest doing the following:

There is a lot of discussion on micropollutants such as pharmaceuticals, chlorinated organics, pesticides/herbicides, and even common things such as artificial sweeteners. The biggest issues are these xenobiotics (not naturally occurring compounds) are passing through biological treatment without degradation. So, a lot of effort is being directed at finding bacteria that can degrade these compounds. In traditional microbiology, we pften screen organisms by sole-carbon source testing. In sole-carbon source testing, you look for microbes that can initate biodegradation of the target compound. Often we can find strains that grow on the target compound. For more difficult compounds, we may need to a cometabolism component. If organisms exist that can degrade these compounds, why are the difficult to treat in wastewater, soils, and groundwater? Here are a few possible explanations:

Oxygen Uptake Rate (OUR or sometimes DOUR) uses a dissolved oxygen probe with a BOD bottle to measure oxygen uptake by biomass. While you could purchase a highly automated, advanced respirometer, for wastewater operations we can do just fine with a standard BOD probe and bottle setup.

Aerobic wastewater treatment microbes consue oxygen when growing. When you saturate a sample with oxygen and then cap the bottle with a DO probe, you measure the oxygen consumed by the bacteria. The observed oxygen uptake per minute gives your the OUR number. Here is a OUR test protocol - https://www.biologicalwasteexpert.com/useful-information.html. Few bullet points on OUR/SOUR and what the numbers mean for operations.

Denitrifcation happens when bacteria begin to use nitrate and nitrite as an alternative electron acceptor. This a complex way to say that the bacteria are using the oxygen in nitrate and nitrite, leaving nitrogen gas. If you get denitrification in a treatment basin, it is a good sign and often required for facilities with nitrite/nitrate discharge limits. If you have denitrification in a secondary clarifier, you can have floating solids with TSS carryover into the effluent. So what can you do to prevent denitrification in secondary clarifiers:

I still like and am fascinated by trickling filter wastewater treatment systems. A simple trickling filter is a tank or tower packed with media on which biofilm grows. Trickling filter biofilm is just like the biofilms you find on Rotating Biological Contact (RBC), MBBR, and any type system where you have a support matrix for biofilm growth.

In an old tricking filter, you can see how biomass develops as the wastewater moves through the media. Early stages have heterotrophic bacteria that remove soluble BOD. Protozoa in highly loaded sections favors amoeba and flagellates. As souble BOD drops and oxgyen increases, you start to see develoment of higher indicator protozoa and appearance of slower growing bacteria such as nitrifiers and sulfur oxidizers. Pros of Biofilm Systems

BOD bottle. Source: Wikimedia commons. BOD bottle. Source: Wikimedia commons. We don't often get back to an old test such as BOD very often. However, I have seen posts where people are seeing BOD5 removal drop and they are wondering why their treatment systems is running well, yet effluent BOD is high. BOD5 is also called soluble BOD. This means that BOD5 represents oxygen demand by most common wastewater components such as sugars, fatty acids, starches, etc. What remains in the BOD5 bottle after 5 days tends to be insoluble or recalcitrant organic compounds. This could be particulates, FOG, long chain hydrocarbons, xenobiotics, pharmaceuticals, lignin, and other slow to degrade or insoluble organics. In theory, if we continued to run the BOD test for 20 days, the microbes would continue to consume oxygen (although at a slower rate) as they degraded these compounds. The BOD20 vs BOD5 can be related to BOD5 removal efficiency by considering how non-soluble or recalcitrant compounds are processed by microbes. For example, consider grease (a very common insoluble in wastewater). If you do not remove grease in pretreatment, the following happens in the biological unit:

Now back to case of BOD5 being possibly generated across a aeration basin. If you expect potential conversion of insoluble organics into soluble (BOD5) forms across your biological unit, you an check by running COD or filtered COD. Besides being a quick test, COD is effective in rapid detection of things contributing to ultimate BOD. |

AuthorErik Rumbaugh has been involved in biological waste treatment for over 20 years. He has worked with industrial and municipal wastewater facilities to ensure optimal performance of their treatment systems. He is a founder of Aster Bio (www.asterbio.com) specializing in biological waste treatment. Click to set custom HTML

Archives

April 2024

|

RSS Feed

RSS Feed