|

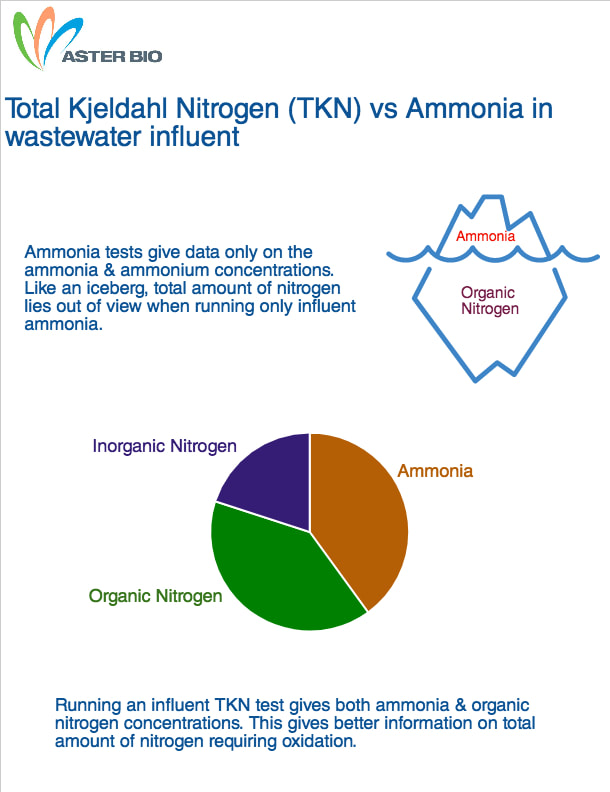

Total Kjeldahl Nitrogen (TKN) measures all organic nitrogen and ammonia at the influent. It is important to remember that much of the organic nitrogen will be converted to ammonia during biological treatment. Alkalinity and oxygen requirements need to reflect the organic nitrogen and ammonia nitrogen concentrations.

I posted this on my LinkedIn account, but think the Environmental Geoomics - molecular biochemistry diagnostics - being developed by Aster Bio is going to give engineers and wastewater operators are new level of insight into the biological composition of their MLSS. With this knowledge, we can see how changes in operations impact system performance and treatment costs. Therefore, I see this as a key inflection point.

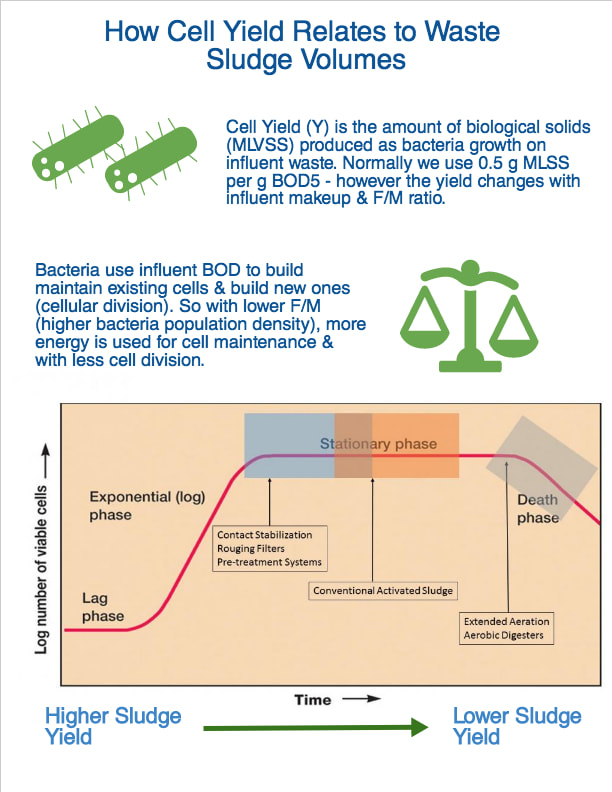

I recently read Andrew Grooves' Only the Paranoid Survive - while it was published in 1996, the discussion of inflection points in an industry are even more relevant today in times of rapid technical changes, international market forces, and customers having access to more options and product information. The book describes the Intel experience of being acted upon during an inflection point related to Japanese competition in memory chips (Intel was on the wrong end of this inflection point) and then the microprocessor (PC) infection point that Intel helped drive. His point was simply, it is better to drive the change rather than be unaware or acted upon by the changes in your market. My experience in inflection points comes from my career in the wastewater bioaugmentation market - we help people biologically treat wastewater via tools for adjusting the microbial populations in the target system. Prior to the late 1990s, advanced biological wastewater treatment was still fairly new to most industrial customers. Most of the business was triggered by spills, mechanical failure, or increased treatment requirements. Increased use of monitoring, diversion, flow equilization, and even tighter control in production areas, began making emergency response less common. Being Acted Upon by the MarketThe bioaugmentation industry tried to market the same core technology to new markets but did not engage in primary R&D to identify innovation opportunities and drive truly new technologies. When Aster Bio was founded in 2003, we realized that new technology was key if we were not going to be a "me too" player in the industry. We started with new production techniques to identify and add new organisms to bioaugmentation products. The early work was the first significant changes in marketed products since the early 1980s. The more sophisticated user and increased regulation of microbial products was a "blip" indicating that market changes were occurring. In creating new products and searching for new markets, we were being acted upon by changes in the market. Opportunity to Drive the Next Inflection PointWith the advent of equipment for high throughput DNA (NGS) sequencing - we finally had a tool for evaluating mixed cultures samples and determining how mixed groups of organisms were treating the waste. At first NGS testing required high dollar equipment, long reaction times, and database/bioinformatics were still being created. Only in the last three years has NGS technology development led to a potential inflection point or a disruptive technology. The challenge is taking output from novelty information to actionable steps at the operator level. At Aster Bio, we decided to not just use the technology for bioprospecting new strains. We see molecular diagnostics and screens - technologies we call Environmental Genomics - as a new tool for directly observing the organisms inside a biological waste treatment unit. Once observed, we can determine how any change - including new influent compounds, operational changes, or biomass optimization - work at a microbial level. Discovering the best microbial makeup for waste treatment allows operators to establish better controls. Aster Bio plans to navigate this technological inflection point by building new molecular testing protocols, wastewater specific microbial bioinformatic databases, and drive improvements in our bioaugmentation products. With the new technologies working in tandem, Aster Bio plans to make biological wastewater treatment units more predictable when faced with challenges with the end goal being lowering overall treatment costs. In aerobic wastewater treatment, waste solids processing & disposal represents a very large cost. This post will cover the basics of cell yield and how changing the F/M can produce fewer solids per unit influent organic removed.

What are waste biosolids? The wasted MLSS contains an aggregate of biological polymers, insoluble organics/inorganics, living & dead cells, and entrained water. The biggest changing variable here for sludge processing is the amount of water trapped in the floc which means more work on dewatering solids. We know that microbial cells divide & use more oxygen when in an environment with high levels of soluble BOD. As the amount of soluble BOD in the water phase decreases, cellular division slows. In high F/M conditions, an abundance of soluble BOD relative to the cells results in much higher respiration rates and percent of living vs dead microbes in the system. In lagoons (by nature a higher F/M system) we often see yields of 0.5 - 0.7 lb MLVSS per lb of influent BOD5 (soluble organic). In activated sludge and attached growth systems, we increase microbial population density giving a lower F/M when compared to lagoon systems. Since microbes always use a portion of the influent BOD for cellular maintenance - the higher number of cells means more energy is going to maintenance than a system with fewer cells. The result is fewer lbs of living cells produced per lb of influent organic. So why not operate at extremely low F/M to make wasting requirements much lower? Well here are the limits to running at extreme low F/M:

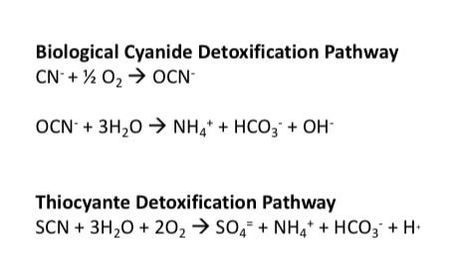

Cyanides are often present in industrial waste water and can be toxic to microbes (especially chemoautotrophic nitrifiers (AOB & NOB) - in anaerobic digesters, CN is highly inhibitory to methanogens. In non-acclimated biomass, we see microbial respiration inhibited by cyanide of 0.3 mg/L. Cyanide is often found in petrochemical, steel/coking, and pharmaceutical waste waters as a by-product of industrial processes. It is not uncommon to see CN concentrations well above the 0.3 mg/L threshold. While cyanide is toxic to many organisms, a large number of microbes have the ability to detoxify cyanide and actually use the carbon/nitrogen for growth. While multiple biological pathways exist, the most efficient is an aerobic pathway. Below are the chemical transformations for CN and SCN.  In practice, I have worked with systems experiencing both inhibition by influent cyanide and shock from sudden increases in cyanide concentrations. Cyanide inhibition is readily addressed by bioaugmentation with cultures having strong CN detoxification pathways. We have identified multiple strains of Pseudomonas, Bacillus, and Rhodococcus with excellent cyanide detoxification and growth on multiple resistant organic compounds including phenol which is often found in high CN wastewater.

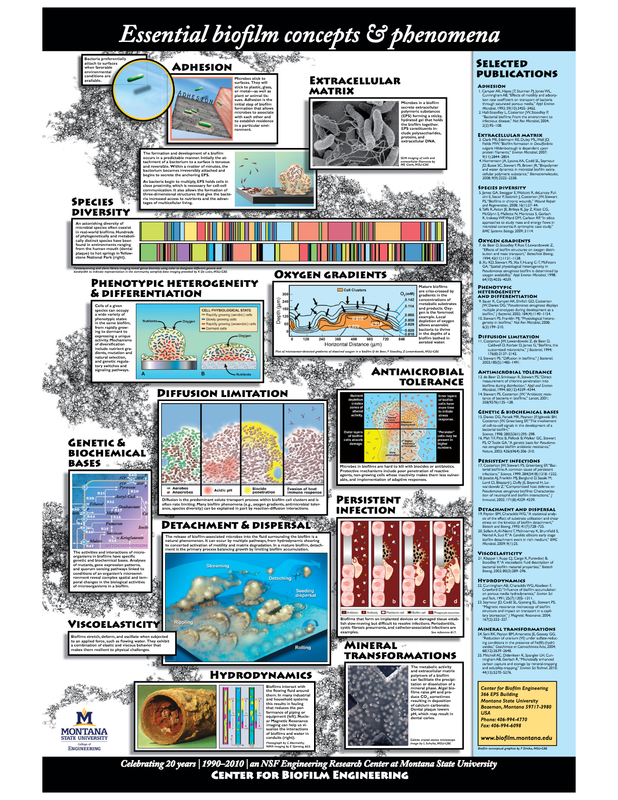

These cultures can be concentrated in shelf-stable form and added to systems with CN related shock or problems with stable CN removal. Once added the CN detoxification starts and the MLSS returns to a healthy state within days as respiration inhibition decreases. Once detoxified, both AOB & NOB return to normal ammonia and nitrite oxidiation rates. Biological cyanide removal can produce CN concentrations in the ppb range at a lower cost than chemical oxidation or metal complexing options. While it cannot treat extremely high CN concentrations seen in some plating and mining wastes, most industrial high CN wastewater can be treated efficiently with biological treatment. I have blogged before on how Aster Bio has been using molecular testing to screen the biomass in wastewater systems. After starting as a way to bioprospect for new microbes in mixed environmental samples, we have discovered that Environmental Genomics testing offers a new way to monitor and troubleshoot biological waste treatment systems. We use a diverse array of molecular tools including 16s rDNA, qPCR, and whole genome sequencing to directly monitor what organisms are present including strains that do not appear on plates or those that require a mixed community for growth.

So far we have used Environmental Genomics to do the following:

As a developing and continuous improved technology platform, Environmental Genomics can be customized to almost any application where directly monitoring microbial populations is needed. Key for successful molecular diagnostics testing is the ability to take complex, raw bioinformatic data and apply it to a working treatment system. Contact me if you have any application ideas for Environmental Genomics testing. We are very excited about the potential for improving waste treatment efficiency and lowering treatment costs. |

AuthorErik Rumbaugh has been involved in biological waste treatment for over 20 years. He has worked with industrial and municipal wastewater facilities to ensure optimal performance of their treatment systems. He is a founder of Aster Bio (www.asterbio.com) specializing in biological waste treatment. Click to set custom HTML

Archives

April 2024

|

RSS Feed

RSS Feed