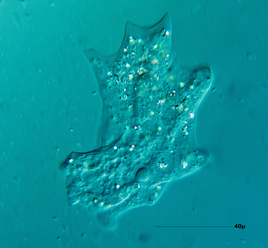

Well screening of industrial wastewater cultures has found some very interesting candidates that produce copious quantities of unique biosurfactants and cultures that tend to be attracted to the grease solid deposit.

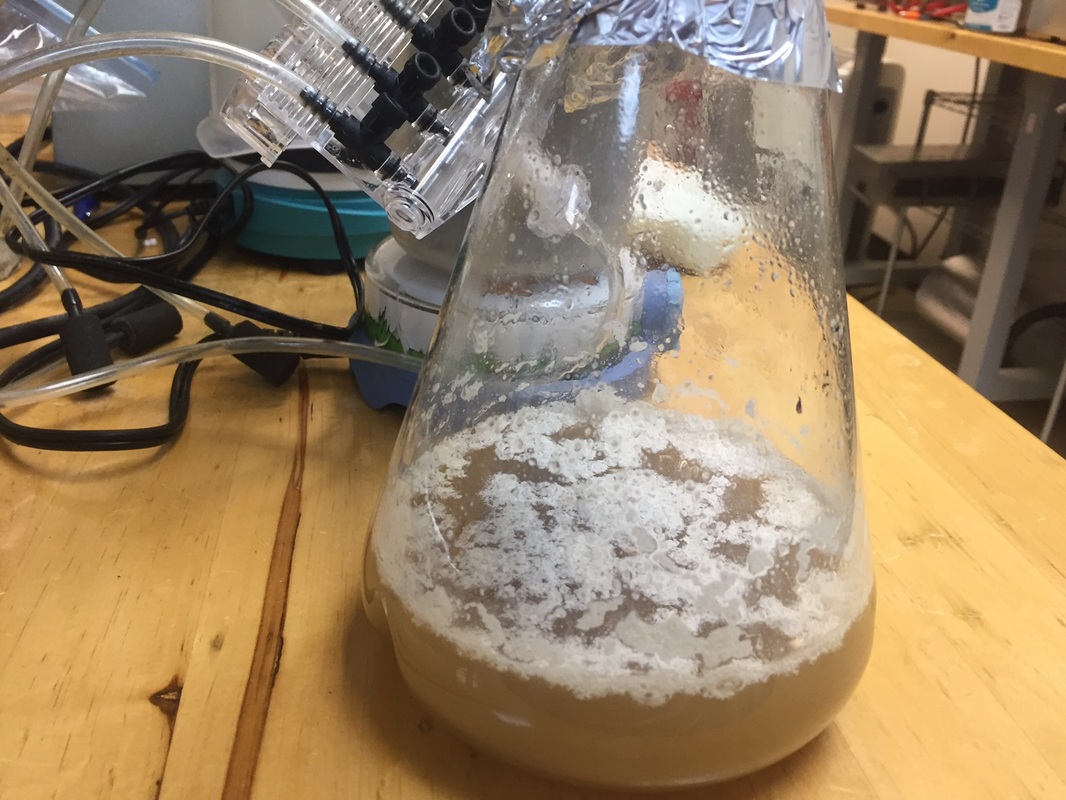

In testing collection system products, we look at the ability of the organisms to shorten the fatty acid chains in grease creating a more soluble fatty acid. In shortening the fatty acids, the organisms are "growing" on the grease in a process called beta oxidation. With the consumption of long chain (insoluble) fatty acids, the organisms also produce extracellular enzymes and biosurfactants that emulsify the grease creating more surface area for the bacteria to attack the grease. The ideal degradation tests include increased water incorporation into the hard grease layer (emulsification) and reduction in weight of the insoluble portion.

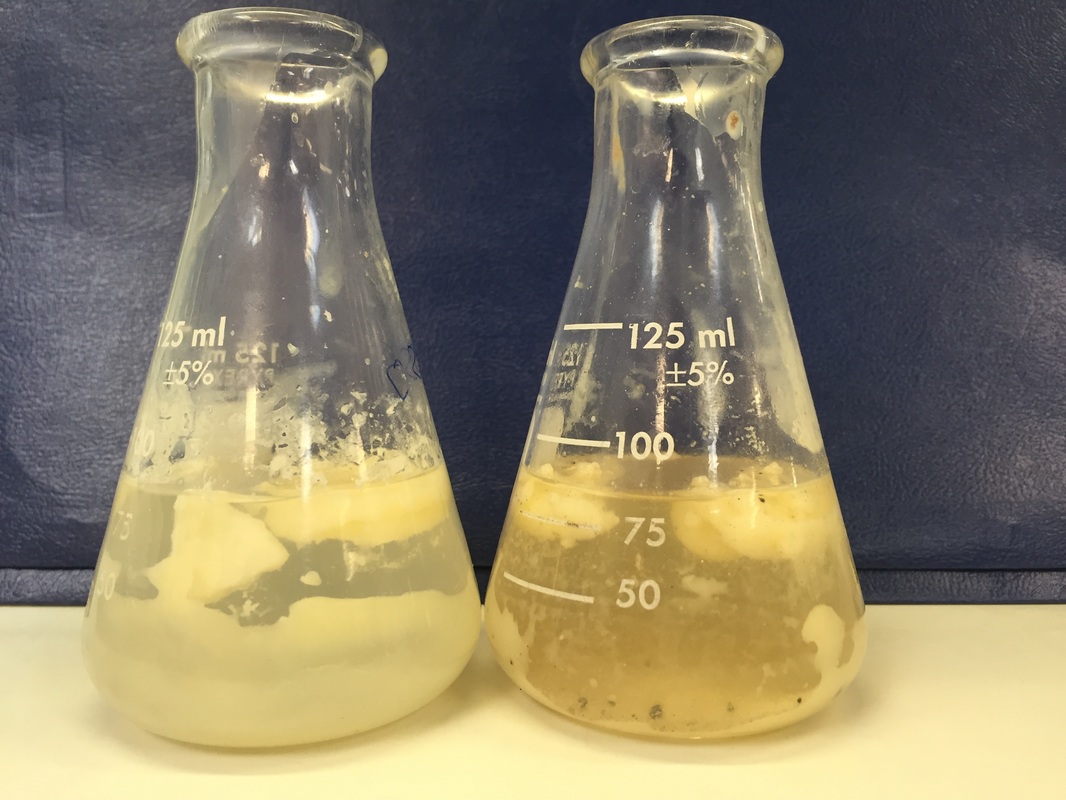

To simulate the process in pipes, we used grease rendered from beef with associated proteins to best match what builds up in the collection system and grease traps. The grease was solidified in flasks. Two test microbe formulations for testing were introduced without any outside surfactants. The test include agitation for 30 seconds per day without aeration/mixing for the remaining time. Temperature was kept at 23 Deg C. (Lab Temp).

Results

The original collection system and grease trap formulations containing only Bacillus sp. performed as expected in lowering the amount of solid grease. Most formulations on the market contain only Bacillus sp. as they have long shelf-life and are easy to grow/preserve. The new Aster Bio modifications included Pseudomonas oleovorans and Rhodococcus erythropolis strains. The addition of these vegetative strains was made via a dry product with 90%+ solubility.

As a picture is worth a 1,000 words, here is a photo of the flasks after 48 hours (below). The flask on the left is the Bacillus sp based product that represents the market standard. The grease has the standard "fluffy" appearance indicating enzyme, biosurfactant, and metabolism. The flask on the right contains the new formulation of P. oleovorans and R. erythropolis. Notices the grease is much "fluffier" and volume as been reduced over 30% more than the Bacillus product.

The results are clear, for systems where bacillus only products have not proven suitable for completely removing grease buildup or where greater efficiency is desired - the use of the new strains could prove quite effective in preventing grease blockages and associated sanitary sewer overflows (SSO).

RSS Feed

RSS Feed