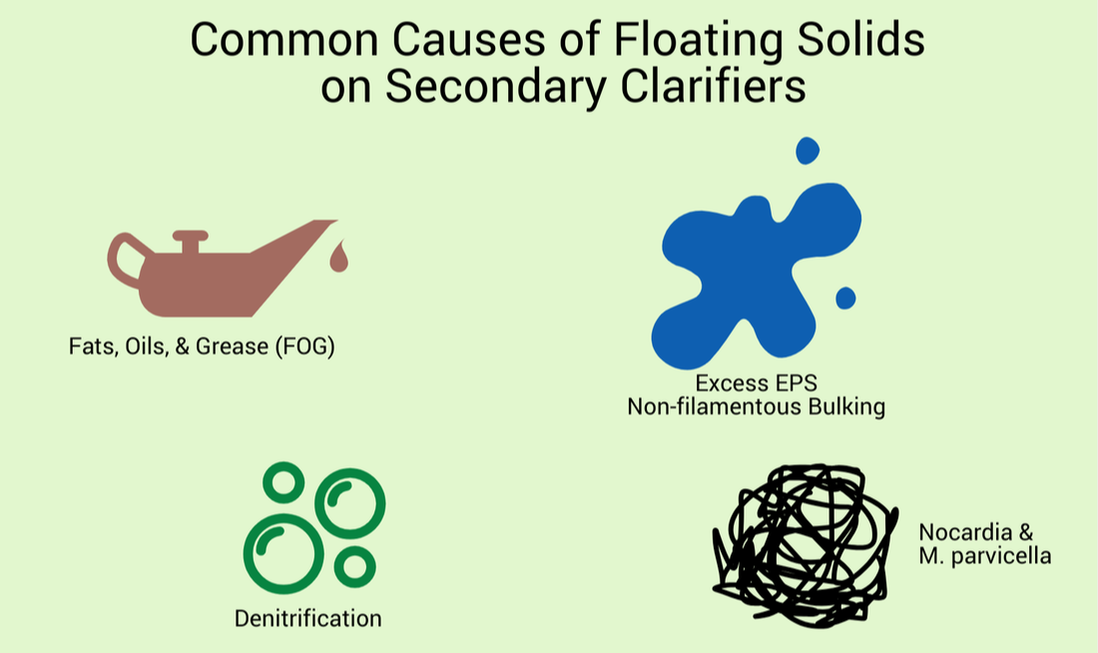

- Excess EPS

While EPS in normal concentrations is needed for floc formation, at times we have excess EPS that creates non-filamentous or Zoogleal type bulking. Non-filamentous bulking sludge is less dense and can trap bubbles of air & nitrogen that acts to float the sludge. - Fats, Oil, & Grease (FOG)

FOG compounds are adsorbed by the floc acting as a sponge. The FOG being less dense than water can disrupt gravity separation and if you have too much FOG acts to float the sludge. - Denitrification

If you have a system with nitrification, soilds can use nitrite/nitrate in resiration while in the anoxic clarifier bed. Denitrification appears as small bubbles released when you disturb the floating solids. Water spray and increaseing recycle pump rate usually solves this problem. - Nocardia & M. parvicella filament foams

Both Nocardia and M. parvicella produce thick foam on the aeration basin. This foam can continue into the secondary clarifiers and create high effluent TSS.

|

Floating solids on a secondary clarifier are usually a byproduct of influent composition or biological processes that have drifted from ideal operations. While some floating solids are not a big problem, heavy solids conentrations can increase effluent TSS resulting in uninteded biological solids wasting. Here are the most common casues of floating secondary clarifier solids:

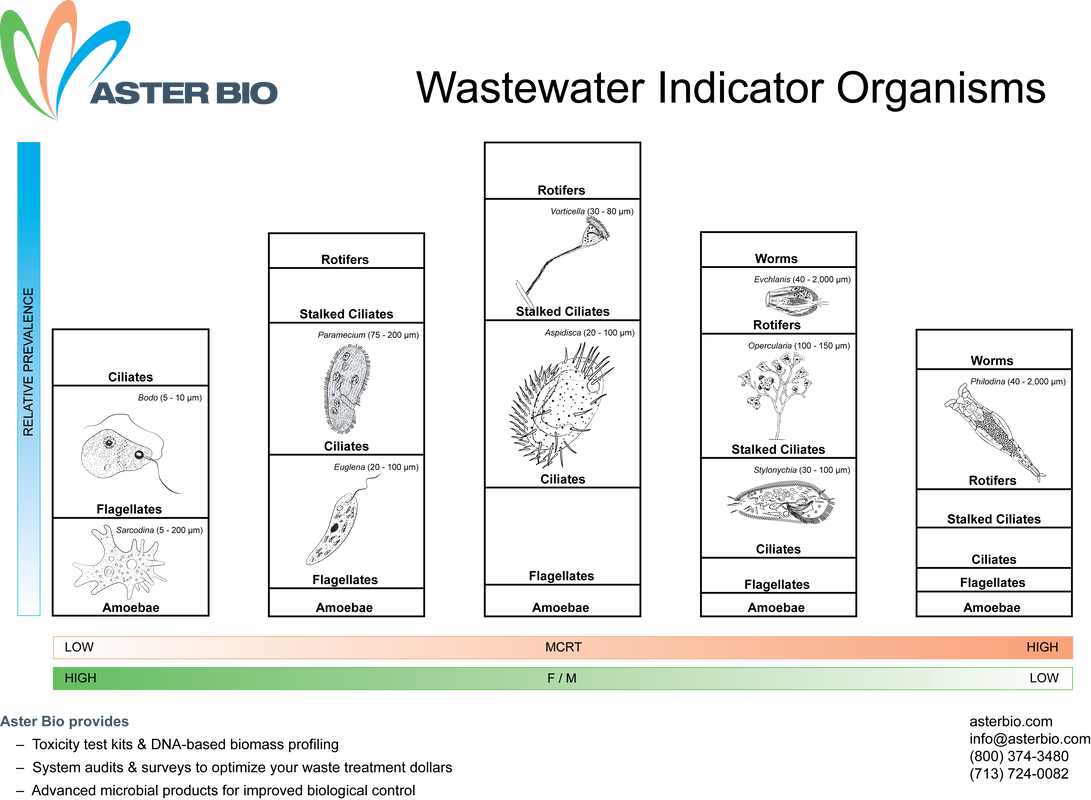

The microscope can give you great information on a wastewater system's biomass health. While expensive phase-contrast, high magnification/resolution microscopes are great, a simple low-cost microscope can provide much of the same information. Let's review what can be done with a microscope similar to the one pictured above.

So just dust off the old microscope and start using it daily. A quick 5 minute look under the microscope using 10x and 40x objectives will give you good information and help improve your monitoring program. If you don't have a bug poster near your microscope, I have included one that we made for Aster Bio here. Your aerobic treatment system has high D.O., good floc formation, and is discharging great quality water. All of sudden, you start to notice small flying insects above the water which are soon followed by small red worms in the MLSS. The flying insects are midge, a native insect that lays eggs on decaying organic matter. It just happens that wastewater MLSS with high D.O. is a perfect environment for laying eggs and incubating larvae. Soon after seeing the midge flies, the worms "blossom".

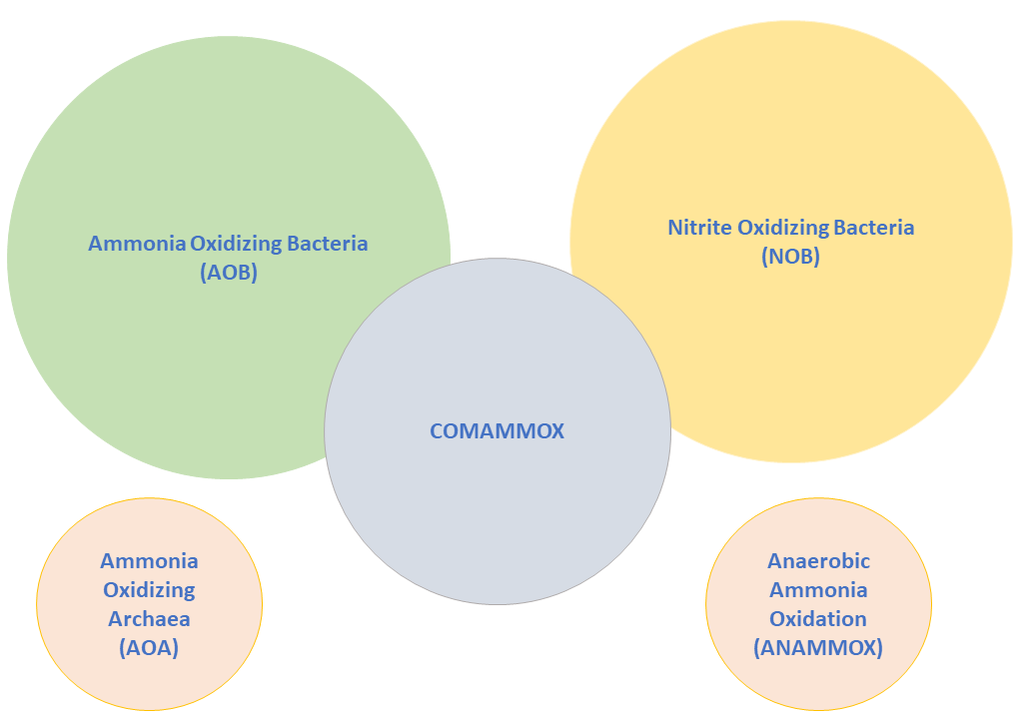

Problems happen when the larvae consum the MLSS - which can cause loss of slower growing organisms such as Ammonia Oxidizing Bacteria (AOB). They can also create effluent TSS if they wash over the clarifier weir. To control midge larvae, the EPA approves the use of Bacillus thuringensis (Bt) spore solutions (kill larvae by damanging their digestive tract) or Strike which is an insect growth regulator (similar to that used in pet flea/tick control). Here is a bit more that I wrote on the midge problem in a previous post: https://www.biologicalwasteexpert.com/blog/whats-eating-my-biomass-red-worms-blood-worms-midge-fly-larvae Another post on ammonia and nitrite removal by microbes! Often grouped as nitrifiers, AOB & NOB cultures must be present if you require significant biological ammonia and nitrite oxidation. Both groups are obligate aerobes and are slower growing than most other wastewater bacteria. This makes AOB & NOB the most common bottleneck in wastewater treatment.

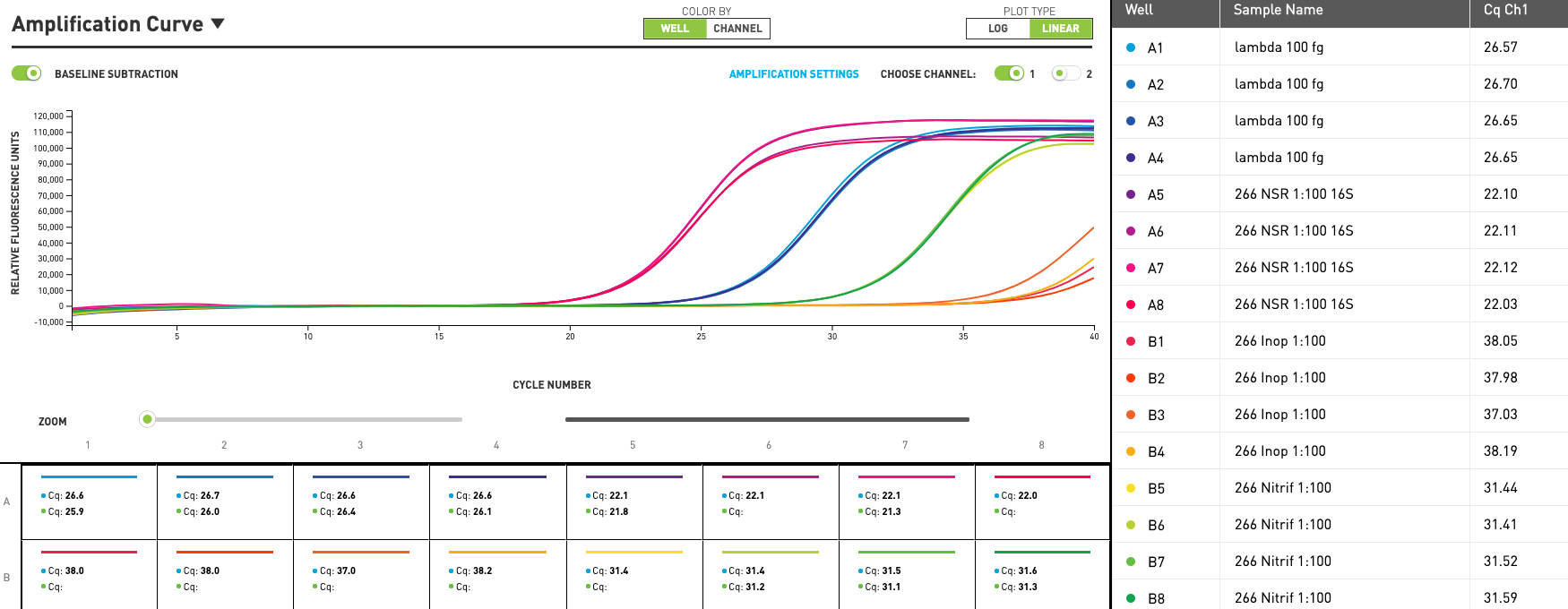

As discussed in my last post, the organisms responsible for ammonia and nitrite removal are a diverse group. Instead of just Nitrosomonas and Nitrobacter, we have a variety of organisms that thrive under slightly different conditions. As they are all key microbes and slow growing, Paul Campbell - Aster Bio's molecular diagnostics guru - has developed a qPCR battery to monitor nitrifiers. qPCR works by fast quantificagtion of specific segments of genetic material. It can be customized to fit the actual poplations in the system. However, you need to make sure the qPCR is a good fit for you biomass which means off-the-shelf type kits are not always the right test. What we now call a qPCR nitrifier pannel can quantify levels of the following:

We are working on development of qPCR for key ANAMMOX cultures. If anyone operates a system with ANAMMOX, we would like to obtain samples to calibrate the tests. Just contact me by email. When talking about ammonia and nitrite treatment in wastewater, we often mention Nitrosomonas (ammonia oxidizing bacteria) and Nitrobacter (nitrite oxidizing bacteria). With the arrival of more advanced testing such as Microbial Community Analysis (MCA or a 16s DNA census) and customized qPCR for specific 16s segments or metabolic pathways, we have the ability evaluate the real organisms removing ammonia and nitrite in working wastewater treatment systems.

After testing industrial, municipal, and even Aster Bio's own "nitrifier" culture reactor, we have noticed that removing ammonia and nitrite from wastewater is a complex process that can involve many different microbes working as part of the microbial community. The most common "types" of nitrifiers are summarized below:

|

AuthorErik Rumbaugh has been involved in biological waste treatment for over 20 years. He has worked with industrial and municipal wastewater facilities to ensure optimal performance of their treatment systems. He is a founder of Aster Bio (www.asterbio.com) specializing in biological waste treatment. Click to set custom HTML

Archives

April 2024

|

RSS Feed

RSS Feed