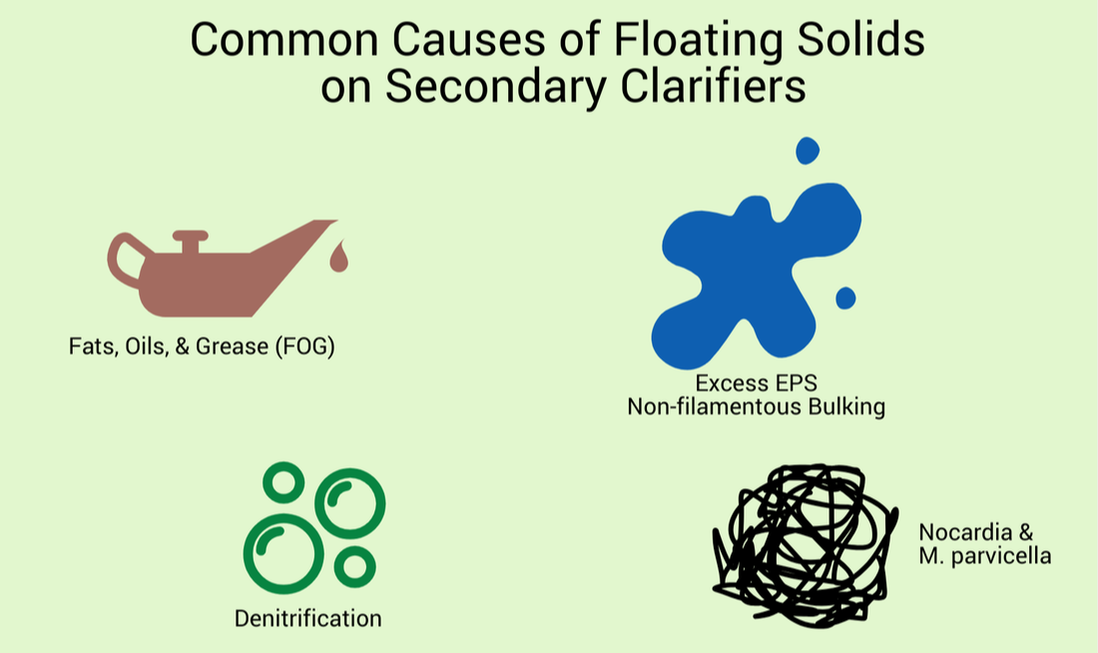

- Excess EPS

While EPS in normal concentrations is needed for floc formation, at times we have excess EPS that creates non-filamentous or Zoogleal type bulking. Non-filamentous bulking sludge is less dense and can trap bubbles of air & nitrogen that acts to float the sludge. - Fats, Oil, & Grease (FOG)

FOG compounds are adsorbed by the floc acting as a sponge. The FOG being less dense than water can disrupt gravity separation and if you have too much FOG acts to float the sludge. - Denitrification

If you have a system with nitrification, soilds can use nitrite/nitrate in resiration while in the anoxic clarifier bed. Denitrification appears as small bubbles released when you disturb the floating solids. Water spray and increaseing recycle pump rate usually solves this problem. - Nocardia & M. parvicella filament foams

Both Nocardia and M. parvicella produce thick foam on the aeration basin. This foam can continue into the secondary clarifiers and create high effluent TSS.

|

Floating solids on a secondary clarifier are usually a byproduct of influent composition or biological processes that have drifted from ideal operations. While some floating solids are not a big problem, heavy solids conentrations can increase effluent TSS resulting in uninteded biological solids wasting. Here are the most common casues of floating secondary clarifier solids:

NJI ELSON

12/23/2019 01:07:23 am

why is solids floating on my Clarifier and Aeration chambers? How can I treat this so that sludge should settle? Comments are closed.

|

AuthorErik Rumbaugh has been involved in biological waste treatment for over 20 years. He has worked with industrial and municipal wastewater facilities to ensure optimal performance of their treatment systems. He is a founder of Aster Bio (www.asterbio.com) specializing in biological waste treatment. Click to set custom HTML

Archives

April 2024

|

RSS Feed

RSS Feed