Biofilters are an efficient way to treat H2S and volatile odorous organic compounds. Unlike chemical scrubbing or odor neutralizing, a biofilter maintains a biofilm on a fixed film media. The biofilm contains a mix of sulfur oxidizing cultures - often Thiobacillus, Paracoccus, Thiosphaera, along with organic acid cultures including Pseudomonas, Paracoccus, Thiosphaera (Note how Paracoccus and Thiosphaera are in both SOX & Organic Oxidizers). In an active biofilter, the biofilm is maintained by a spray system that adds nutrients and pH adjustment to keep the biofilm at maximum activity. The biofilters are sized based on expected loadings and air volumes to be treated. If sized correctly, they are very efficient and almost appear as a magic box.

|

After touring the Pearland, TX new wastewater treatment facility this week, I saw many newer treatment technologies in practice. The most amazing thing was the facility is very close to neighbors with no odors. Even standing near the headworks, there was no apprecialble odor. Best yet, they did not have any perfume or odor adsorbing misting. What was being used were two biological filters. One treated the lift station and a second served the headworks.

Biofilters are an efficient way to treat H2S and volatile odorous organic compounds. Unlike chemical scrubbing or odor neutralizing, a biofilter maintains a biofilm on a fixed film media. The biofilm contains a mix of sulfur oxidizing cultures - often Thiobacillus, Paracoccus, Thiosphaera, along with organic acid cultures including Pseudomonas, Paracoccus, Thiosphaera (Note how Paracoccus and Thiosphaera are in both SOX & Organic Oxidizers). In an active biofilter, the biofilm is maintained by a spray system that adds nutrients and pH adjustment to keep the biofilm at maximum activity. The biofilters are sized based on expected loadings and air volumes to be treated. If sized correctly, they are very efficient and almost appear as a magic box. Since Aster Bio has been performing Microbial Community Analysis (MCA) genetic testing on MLSS from a wide range of industrial and municipal samples, I have learned much more about the organisms causing non-filamentous bulking and why past control methods were not very effective. I don't know how many times I advocated adding nutrients, wasting high EPS sludge, and trucking in MLSS & using bioaugmentation cultures; only to have bulking return later. Below is a summary of what causes non-filamentous bulking and why these bacteria can go from beneficial to a problem.

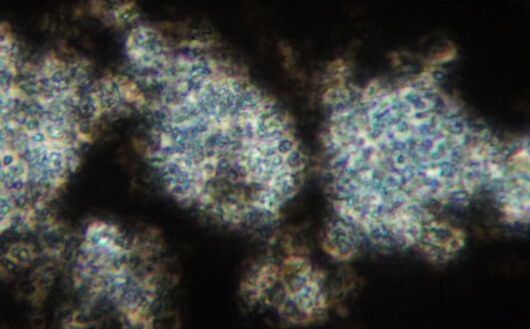

Non-filamentous bulking or excess extracellular polymeric substances (EPS). How do you know if you have excess EPS?

EPS is very important for floc formation in suspended growth and for biofilms in attached growth wastewater treatment plants. Wastewater plants were designed to operate in decline phase growth where microbial division slows and cells begin to form aggregates. Key to aggregate formation is the production of EPS. Consisting of polysaccharides, proteins, nucleic acids, and a variety of metabolic byproducts; EPS functions to keep cells protected and viable under the stress of low soluble organics (food). Another function of EPS is the accumulation/storage of nutrients including N, P, and metals. Under normal operations, the proper amousnt of EPS is needed for solids removal and helps remove phosphates in biological nutrient removal systems. The problems happen when the biomass generates excess EPS. Main organisms responsible for non-filamentous bulking Using Microbial Community Analysis (total MLSS microbial census) technology, we have identified the major contributors to non-filamentous bulking as:

Past Methods

New monitoring & control strategies

|

AuthorErik Rumbaugh has been involved in biological waste treatment for over 20 years. He has worked with industrial and municipal wastewater facilities to ensure optimal performance of their treatment systems. He is a founder of Aster Bio (www.asterbio.com) specializing in biological waste treatment. Click to set custom HTML

Archives

April 2024

|

RSS Feed

RSS Feed