Carbohydrates

Carbohydrates such as sugars, starches, and cellulose are among the ideal feeds for anaerobic digesters and often improve methane yields. Operators should keep in mind the ease at which carbohydrates are converted simple acids in the digester. In order of ease:

- Sugars

- Starches

- Cellulose & Hemi-cellulose

- Ligno-cellulose

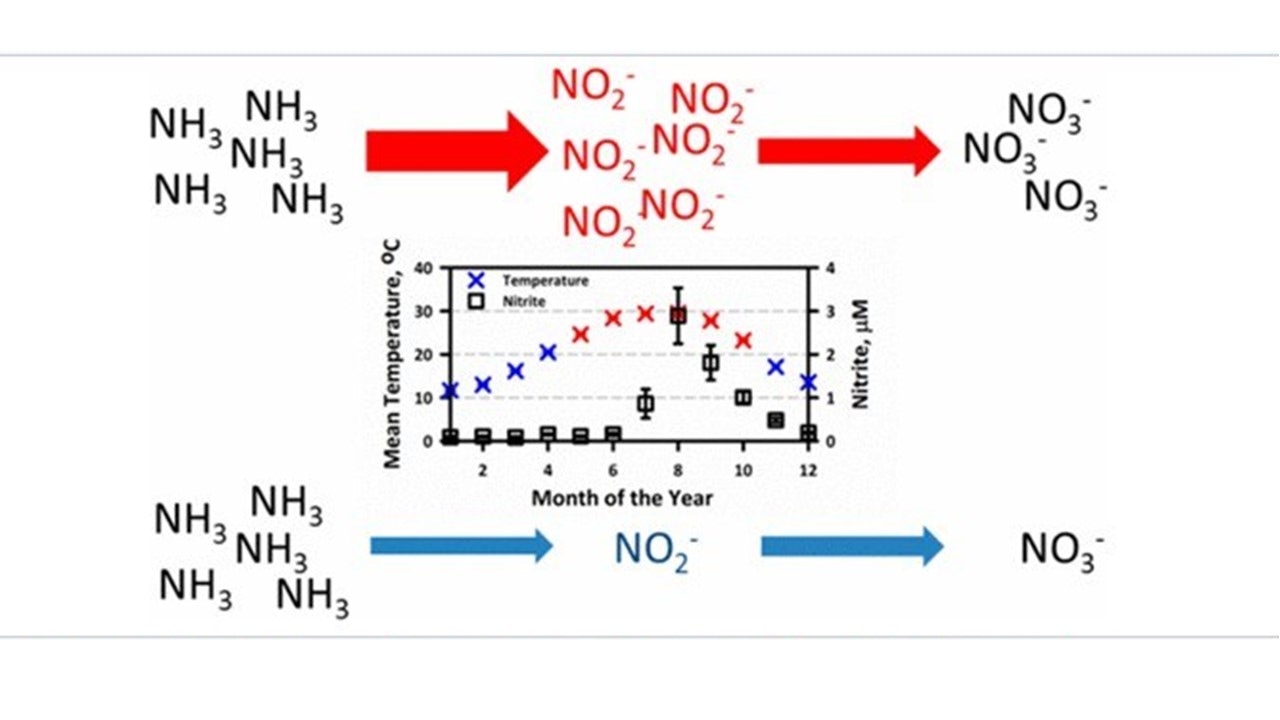

Proteins readily degrade to amino acids that are further converted by bacteria into acetate. The amine groups do lead to the generation of ammonia. Ammonia in un-ionized form (NH3-N) can rapidly become toxic to methanogens at 100 mg/L. Substantial amounts of un-ionized ammonia form only when pH increase well above the target 6.7 – 7.4 range. Ammonium (NH4+-N) is much less toxic to methanogens and can be tolerated above 1,500 mg/L. System treating high protein wastes, should monitor ammonia and pH closely.

Fat & Long Chain Fatty Acids (LCFA)

Digesters receiving mostly wastewater treatment plant biological solids tend to have lower than needed methane production. With high energy potentials, grease trap waste offers a way to increase methane production. Remember FOG used to characterize grease trap waste contains mainly long chain fatty acids rather than pure fats. Most grease traps have microbes producing lipase which breaks down the grease molecule into constituent glycerol (which is used quickly) and long chain, insoluble fatty acids forming the grease cap. In the anaerobic digester, the long chain fatty acids are converted into both acetate and hydrogen via a multiple step anaerobic oxidation process. The LCFA pathway is slower than that of carbohydrates and proteins, and the produced H2 must be removed by H2 utilizing methanogens as increasing levels of H2 in the digester make further anaerobic oxidation thermodynamically impossible. On a good note, the methanogens using H2 grow more rapidly than the acetate using methanogens. Another challenge with adding concentrated LCFA wastes is the potential buildup of volatile fatty acids and associated low pH. The acid formation can continue well below a pH of 6.5 where methane production becomes inhibited.

Back to how much FOG (LCFA) can I add to an anaerobic digester

It should be clear that the amount of FOG that can be added to an individual digester depends on site-specific factors. Operators need to consider the following:

- Digester design & operating specifications

- Know current influent makeup – it is more than just a COD number

- What are the organic components & their convertibility to methane

- Micronutrients

- Sulfate/Sulfides

- Inhibitory metals

- Inhibitory organics

- How to increase monitoring when adding new solids to the digester – pay close attention to digester ammonia, alkalinity, and VFA. In the off-gas measure CO2 and methane.

- Gradually increase the FOG addition over time to allow for the microbial population to develop to the new influent makeup. There will be an increase in anaerobic LCFA oxidizers and H2 utilizing methanogens – but they take time to develop into needed populations.

RSS Feed

RSS Feed