- What container should be used for settling tests?

The reason for the larger 2L size is that there is less interference from glass or plastic walls on the settling biomass. While 1L is commonly used, any smaller size has interference. But, the biggest rule is to be consistent and use the same method each time. - Why 30 minutes, when my clarifier has a 2 hour residence time?

The 30 minute settling time is long enough to give information on how the solids will behave in the clarifier. Also, remember this is a batch test without any flows entering or leaving - which happens in the clarifier. The SV30 can be made more useful by recording sludge levels every 5 minutes. Older sludges (low F/M) settle quickly leaving high turbidity, younger sludge (high F/M) does not compact well.

- What are the units in the SV30 test?

SV30 is really a ratio of volume settled sludge per volume mixed liquor. If you use a 1L cylinder it is ml settled sludge per Liter. So we often say SV30 of 400 meaning 40% of the volume occupied by settled sludge after 30 minutes. - How do I calculate SVI from SV30?

When you change mixed liquor suspended solids concentration, it makes sense that the SV30 also changes. To make the SV30 more "standardized", the SVI was created. SVI is calculated by taking the SV30 number and dividing by MLSS in grams (some people use MLVSS instead of MLSS). As in all monitoring, just make sure you use the same test procedure each time. Systems with SVI above 150 are said to be bulking with the ideal range often being given as 100 - 120. Again, this is system specific and develop a range for local equipment and flows.

|

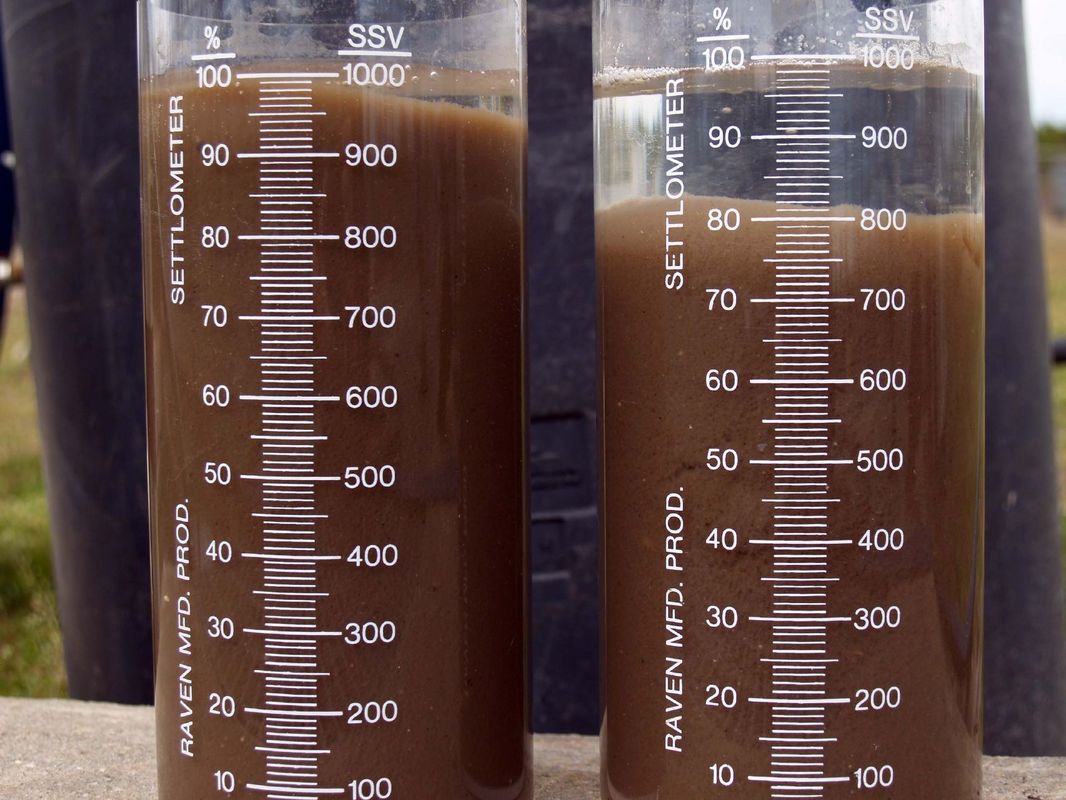

The traditional SV30 test is done in either a 1L graduated cylinder or 2L settleometer (a graduated beaker of sorts).

While biological waste treatment usually focuses on water or soil, the technology can also be very useful for treatment of air. Biofilters containing biofilms can treat air as it passes for a number of compounds. The filters are designed to channel air over the media surface while also maintaining humidity and nutrients needed for microbial growth. Unlike wastewater, oxygen is abundant so microbial activity is aerobic. The biofilters can replace activated carbon and other physical/chemical adsorption systems.

Benefits to replacing adsorption systems include:

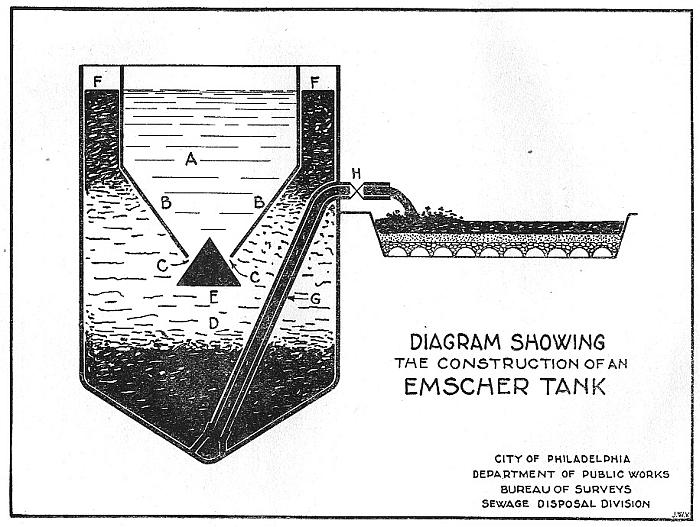

The Imhoff Tank was developed in the early 20th century for treating wastewater. The tank was an improvement over existing septic tank technology and served as a bridge before more advanced systems were introduced. So why talk about Imhoff tanks today? Well for developing countries or small communities without access to significant capital or experienced operators, an Imhoff tank offers a robust, compact unit to pretreat wastewater.

The Imhoff tank is a compact treatment unit usually made of concrete and build in-ground. The Tank consists of a V-shaped settling chamber with a residence time of one to three hours. At the bottom of the V, settled solids drop into a lower anaerobic chamber that starts sludge stabilization. Scum and gas escape from the anaerobic chamber to gas vent channels running parallel to the V-channel (sedimentation chamber). The anaerobic section also has a V-shape for solids accumulation where pumps or screws can eventually remove digested solids for disposal. As for performance, the Imhoff tank removes between 25 - 50% of inlet COD. With a relatively short residence time in the settling chamber, odors associated with anoxic/anaerobic wastewater are prevented. The anaerobic gases including methane are vented in the side channels with the scum layer helping control organic acid and sulfide odors. As with all anaerobic pretreatment, pathogen removal is low. Normal operations include checking scum & anaerobic chamber sludge levels. Digested sludge should be removed with solids being treated in drying beds or composting - to ensure pathogen removal. Water passing through the settling chamber, still contains substantial COD/BOD, ammonia, phosphorus, and enteric organisms. Further treatment is required. In traditional Imhoff systems, the discharged water enters facultative lagoons, rock-reed filters, trickling filters, or other low-cost aerobic/oxidation system. Imhoff tanks with low construction and operational costs are suitable for communities with flows up to 950 cubic meters or 250,000 gallons per day. Benefits of Imhoff Tanks

Wastewater treatment facilities are now faced with permits requiring phosphate removal before discharge. If discharged into receiving streams, excess phosphate often triggers algae blooms including problematic "toxic" algae that cause off-flavors in drinking water and other direct toxicity to wildlife. To meet these new permits, engineers are installing a variety biological and chemical technologies to remove soluble phosphate from the water and entrap the phosphate into sludge. Then the question is what to do with the produced sludge - especially the sludge generated from metal salts phosphate removal technology.

Several companies have introduced new technologies for removing soluble phosphate in a form suitable for use as a fertilizer. This is important as most fertilizer grade phosphate is mined and mined phosphate is getting more expensive as natural deposits are depleted for agricultural fertilizer. The most promising new technology is based on using biological processes to concentrate soluble phosphate and nitrogen in water. This is already done during sludge digestion in anaerobic digesters. As solids going to the digester contain high levels of N & P, as the solids are digested releasing carbon in the form of methane and carbon dioxide; both phosphorus and nitrogen are released into solution. The resulting supernatant is much higher in both N & P than the influent. The new process includes raising the digester supernatant pH to between 7 - 11. Magnesium salts are then added with mixing. The equal molar ratios of P:N:Mg result in the formation of struvite crystals which drop out of the water removing soluble nitrogen and phosphorus. The crystals are collected and are suitable for use as fertilizer. The struvite crystal has a fertilizer value of N - 5%, P2O5 - 28%, and Mg - 10% and is great as a time release fertilizer. Lift-stations often have problems with grease buildup which causes problems with equipment, corrosion and odors. The "grease" is actually a mix of long chain fatty acids which result from initial decomposition of fats & oils in the collection system. Bacterial lipase splits the glycerol from the fat as an easy source of energy. This biochemical step results in three long chain fatty acids. While anaerobic decomposition occurs, the fastest way to degrade insoluble fatty acids is via aerobic beta-oxidation pathways.

Control of the FOG in lift-stations is often done using a combination of physical and chemical approaches. Water jets and vacuum trucks can loosen and collect grease deposits. Often surfactants/solvents are added to liquefy the grease for easier removal. Solvents, even natural ones such as d-limonene, emulsify grease and allow any FOG not removed by vacuum truck to pass down to the treatment plant. Since the 1990s, many municipalities have used microbial blends for grease control in lift-stations. The microbial products are found in liquid, solid block, or dry powder form. Here is a quick run-down on what they contain:

Over the past several years, we have been evaluating ways to improve biological activity in the lift-station. We looked at using various blowers and mixers to determine:

With over a year of testing, we have noted the best approach is to combine the aeration/mixing with the microbes. The aeration/mixer can be in almost any form. The key is to mix and increase the bacteria/oil/water interface - with mixing we have enough oxygen for beta oxidation pathways. With treatment, grease does not build up into a solid cap. Any grease that accumulates is easily washed off with water spray. FOG to the treatment plant does not increase as seen with using surfactant/solvent treatments - as the fatty acids are being converted from FOG into soluble organics (BOD5) which is not a problem for most treatment plants. |

AuthorErik Rumbaugh has been involved in biological waste treatment for over 20 years. He has worked with industrial and municipal wastewater facilities to ensure optimal performance of their treatment systems. He is a founder of Aster Bio (www.asterbio.com) specializing in biological waste treatment. Click to set custom HTML

Archives

April 2024

|

RSS Feed

RSS Feed