Strengths

- Allows for higher MLSS concentrations than conventional activated sludge (CAS)

- Total separation of solids and ultrafiltration improves effluent quality - ability to meet stringent permits

- Smaller system size than CAS

Weaknesses

- More expensive to operate

- Need to have pretreatment to remove grit and other particulates that can damage membrane

The ability of membrane to physically separate solids from the effluent leads many operators to assume that filamentous bacteria and non-filamentous bulking that cause problems in secondary clarifiers are not important to MBR operation. While not as susceptible to problems with bulking as CAS, MBR systems can develop problems related to bulking organisms.

Membrane systems are monitored on:

- Transmembrane Pressure (TMP)- force required to drive water through the membrane pores

- Flux Rate - flow per unit area of membrane

- Permeability = Flux Rate / TMP

Both filamentous and excessive EPS (non-filamentous bulking) organisms can limit membrane effectiveness. By clogging pores and fouling membranes, bulking results in decreased flux rates and higher TMP. This fouling can be countered by increased membrane backflushing and cleaning. Both of which reduce membrane operational time - less effluent per surface area of membrane. In practice, we have encountered MBR systems where discharge limits due to bulking create expensive bottlenecks in the treatment process.

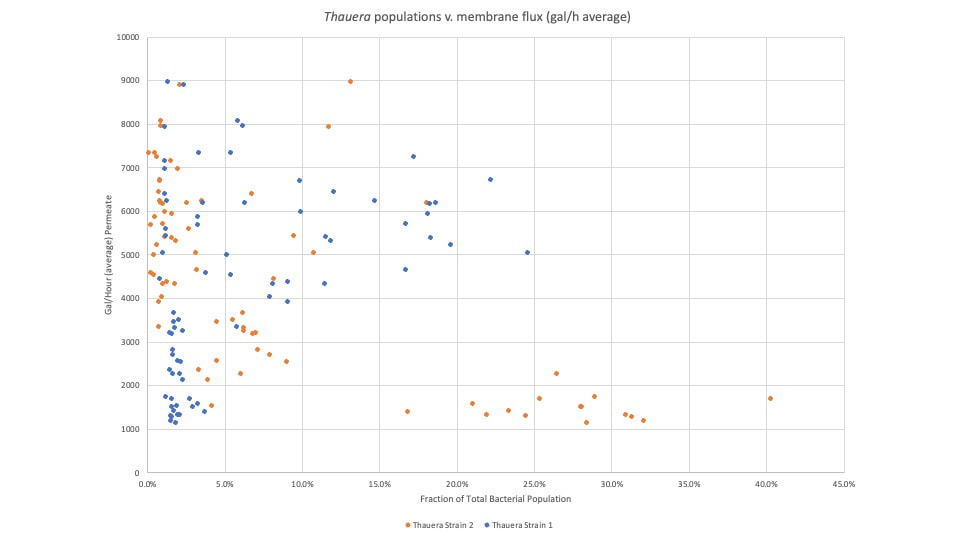

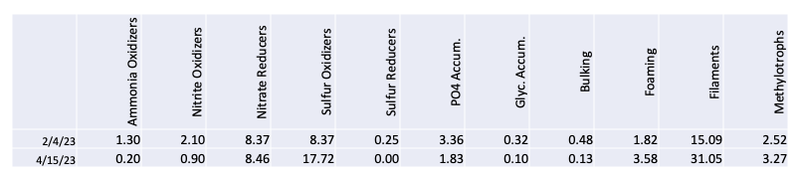

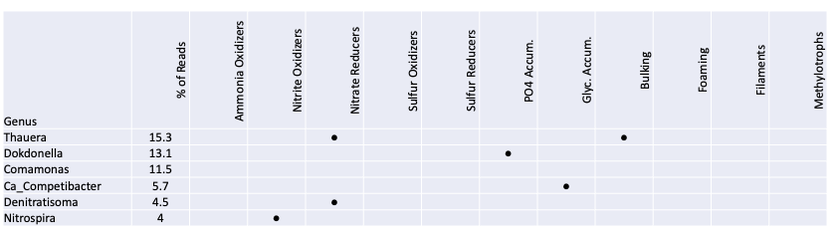

Below is an example of non-filamentous bulking by a Thauera sp. was limiting flux rates in a MBR system. We helped this client develop a qPCR test for key problem organisms and worked on operational methods to reduce likelihood of diminshed flux rates. Note how one strain was responsible for reduced flux rates and monitoring this population was a key performance indicator.

RSS Feed

RSS Feed