First the F/M ratio is often based on MLSS (total solids) or MLVSS (volatile solids). This is the M in the equation. While we often say this is the "bacteria" or "bugs", the real answer is living bacteria cells only represent a percentage of this mass. As we get lower F/M ratios, the amount of living bacteria compared to dead cell mass, biopolymers, and adsorbed organics drops resulting in what we call "old biomass". If the percent of living bacteria cells continues to decline because of limited "food" the amount of biopolymers that hold the floc together begin to decrease and you will see the pin floc associated with old sludge. By looking at the incoming organics (F or Food), the F/M ratio is a forward looking number (even if we use 5 day old BOD5 numbers - as it takes a sludge age (MCRT) or two for within control feed changes to fully impact the biomass.

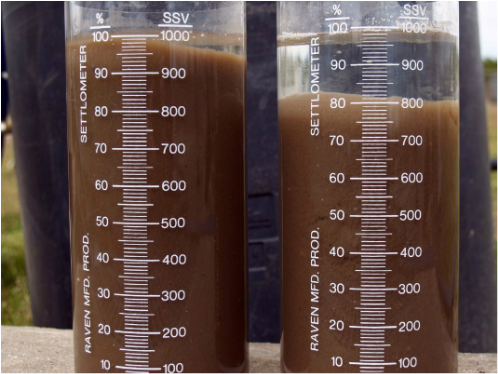

The SV30 test is a picture of current settling rates. It does not predict future performance. Changes made based on SV30 should be made slowly in steps as these changes, with the exception of polymer addition, take time to change the floc structure (SV30's underlying cause).

Therefore, if continued low influent organic loadings creates low F/M and a gradual decrease in the percent active biomass. Eventually this will impact floc structure and lead to pin floc and turbidity in the SV30 if the low influent food concentrations continue. However, do not make big changes in operation based on a few days of low loading as changes take up to two sludge ages to manifest their full impact.

RSS Feed

RSS Feed