Phenol shocks are one of the most common sources of upset in industrial wastewater treatment systems. While phenol is biodegradable, it was also the first antiseptic used in the 19th century. In industrial wastewaters, spikes in phenol often cause problems maintaining ammonia oxidation and in larger spikes can cause deflocculation. Among the marketed solutions are the use of oxidant pretreatment step and adding activated carbon to adsorb phenol. Another solution is to use equalization tanks to store the high phenol wastewater and then meter the strong wastewater back into the biological unit. Often the limiting factor for phenol treatment is the high oxygen demand for aerobic decompostion of phenol. Otherwise, bacteria including Pseudomonas and Rhodococcus species are very tolerant of high phenol concentrations and able to completely degrade phenol as a sole carbon source.

So if you have high phenol or other quasi-toxid organic released to your treatment system, here is the best protocol for protecting the biological treatment unit.

- Divert the high strength water into storage or EQ tanks.

- Ensure both N & P in the biological treatment unit is sufficient to maintain C:N:P ratios.

- D.O. needs to be maintained above 2.0 mg/L to ensure needed biological activity. I have also used hydrogen peroxide metertedin the system to boost dissolved oxygen during high loading events. Bacterial catalase releases oxygen from peroxide. Be careful to not overdose peroxide which can damage biomass.

- If spill has reached the system or not all the wastewater can be diverted, you can use powdered activated carbon to adsorb phenol.

- If biomass has been damaged and fast recovery is important, adding bioaugmentation cultures can help speed up recovery and blunt the impact of high strength influent. Just make sure the cultures that you are adding are selected for the specific waste compounds. For example, what works on cellulose/starches is probably not the culture for phenol or solvents.

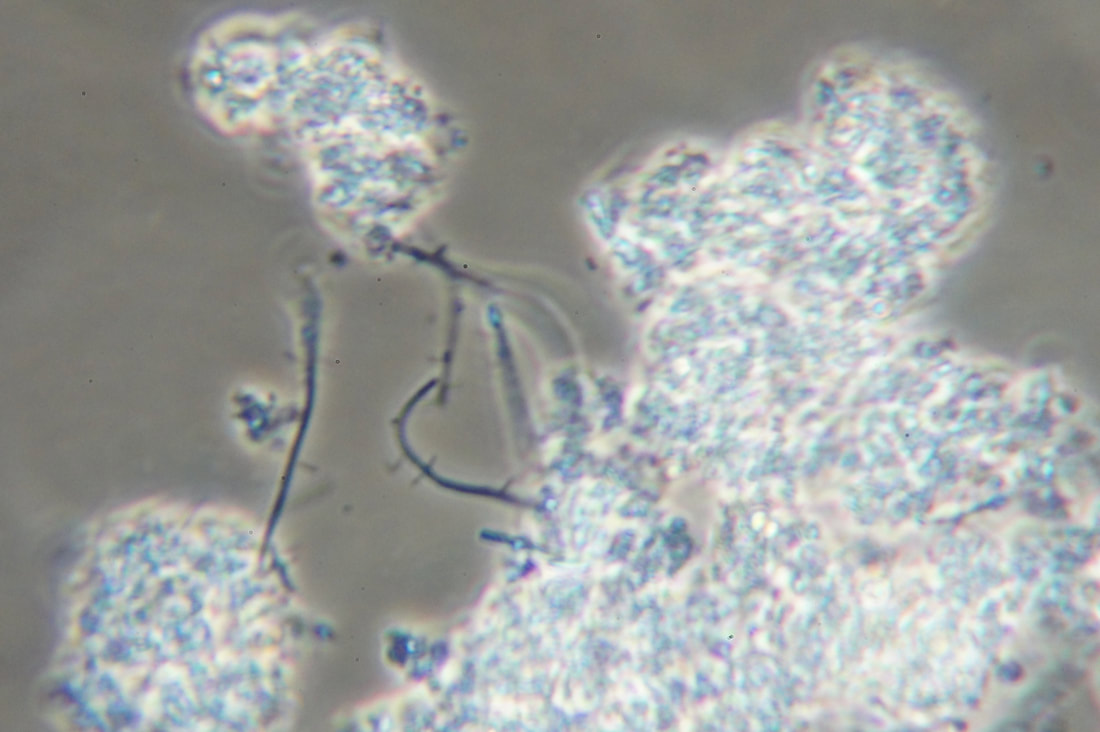

- Monitor closely - this is extremely important. Use microscopic exam, oxygen uptake rates, ATP (if done), effluent turbidity/TSS, and ammonia residuals. If you see warning signs of moving backwards on the growth curve (out of decline phase growth), then stop forward flow from the storage tanks.

RSS Feed

RSS Feed