As I biological treatment person, I was involved in multiple field tests that used biological maintenance options. Of course some worked better than others, this post will detail some of the things that we found when going from lab to the field.

As an insoluble organic, grease (usually long chain insoluble fatty acids) causes problems in the following ways:

- Sticks to pipe walls which restricts flows. In severe cases, this can cause SSO.

- Harmful to lift station equipment and anaerobic zones under grease film produce H2S

- In wastewater plant the FOG is slow to degrade and can cause floating sludge/scum

- Can promote hydrophobic microbe growth - the most seen is Nocardia

So what did we learn from numerous field tests

Grease traps

Grease traps are not checked enough - often restaurant managers barely know they exist. Inspecting the trap can lead to timely pumping. Biological additives, when used in a maintenance program, can reduce BOD5 and FOG entering the colletion system. The best biological products in testing were metered liquid formulations containing fatty-acid degrading cultures. Side benefits to stress to restaurant managers include - fewer mystery odors in parking lot and reducing emergency plumber call outs for drain line clogs.

Gravity mains

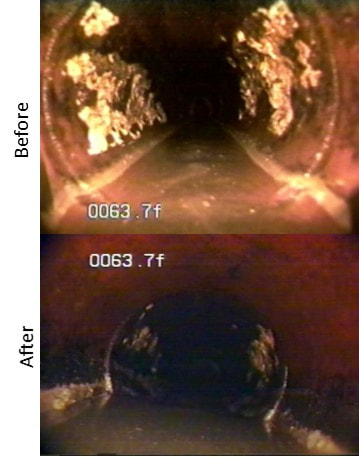

We looked at manual dry product dosing and adding liquid cultures with a metering pump. The liquid by virtue of more frequen dosing fequency was more effective. Grease accumulation rates decreased and the grease that accumulated was partially degraded and easily jetted from pipe walls. Camera guys noted the grease was "fluffy" versus the normal hard grease seen in problem lines. Keys for success in treating gravity mains included dosing upstream of the problem. It is best to do a survey and find sources of the grease and dose at a point where grease degrading biofilm can be established upstream of the problematic site. This is where experience comes into play and we can use tools to find the best dosing point.

Lift Stations

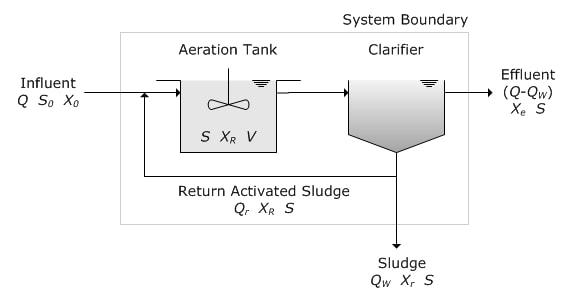

Having worked with time-release blocks, manual dry products, and metered liquid blends; I have found that the best product depends on lift-station size, amount of grease, and access issues. Often if we treat grease traps and gravity mains upstream, the lift-station grease is controlled. This is because bacteria are able to grow on pipe surfaces forming a grease degrading biofilm. This biofilm contains aerobic and microaerophilic organisms that are the same ones seen in healthy wastewater treatment plants. So by treating collection systems, you are moving biological wastewater treatment upstream. We have used this to lower loading to WWTP that are undersized for increased influent loadings while waiting on new treatment plant construction.

Here are a few take-home messages from the trials:

- Grease degrading microbes come in many forms - it is not just Nocardia. You can favor specific ones to prevent Noardia foams on aeration basins by doing upstream pretreatment.

- It is best to keep grease out of a system via education. However some still enters the collection system. Treating upstream is most efficient.

- Treatment is not as simple as ordering something out of a catalog and hoping for the best. A collection system treatment program should involve investigation, selecting proper product for the location, and finding proper addition points.

- Collection system programs behave by natural laws. There are no bug steroids, super bugs, or anything that has a mystery. We know that controlling the environment, promoting the right organisms, and seletively modifying microbial populations can achieve treatment goals.

RSS Feed

RSS Feed