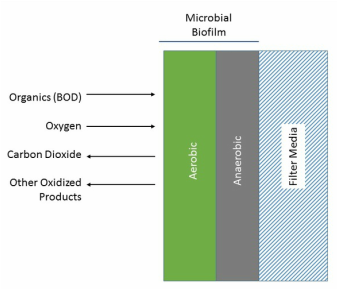

As with all fixed film systems, the basis for performance is the establishment of a stable biofilm on the carrier. As with the trickling filter, the biofilm works in the same manner.

One of earliest retrofit suspended growth systems utilized polyurethane foam pads with a bulk density of 0.95 (or slightly lower than water). Adding the pads at 20 - 30 by basin volume with screens to keep the pads in the aeration basin, results in an equivalent MLSS concentration of 5,000 - 9,000 mg/L. Note that this system maintains the biomass recycle from the secondary clarifier.

Another retrofit, is the moving-bed biofilm reactor modification where the aeration basin is filled with 25 - 5i0% tank volume of polyethylene solid carrier media. The media and associated biofilm are suspended by aeration and maintained in the tank by a screen leading to the clarifier. What is good about the MBBR system retrofit, is the secondary clarifier does not recycle biosolids to the aeration basin - the clarifier only settles sloughed solids. Both oxygen and mixing are provided by coarse bubble difffusers that have much fewer problems with fouling when compared to fine bubble diffusers. Additional sections can be used for denitrification by replacing aeration with mechanical mixers to provide for media under anoxic/anaerobic conditions needed for nitrate/nitrite removal to nitrogen gas.

RSS Feed

RSS Feed