Microbial Colonization:

- Microorganisms, including bacteria and fungi, naturally colonize the media in the biofilter.

- Specific microbial strains are selected for their ability to metabolize and break down hydrogen sulfide and volatile organic acids.

- Colonization by microorganisms takes time at startup or following a loss of viable biomass in an operating system. Aster Bio has successfully used bioaugmentation to reduce time required for startup using sulfur oxidizing and volatile organic acid degrading organisms.

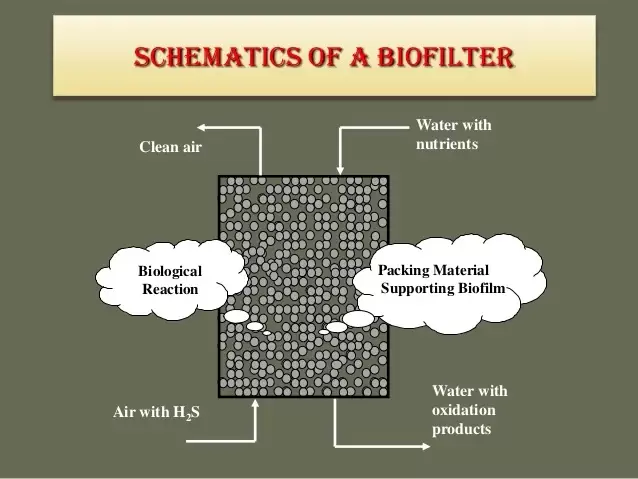

- Odorous air containing hydrogen sulfide and volatile organic acids is introduced into the biofilter.

- The air is evenly distributed through the biofilter bed to ensure contact with the microorganisms.

- Microorganisms on the biofilter media surface metabolize the odorous compounds through enzymatic reactions.

- For hydrogen sulfide, bacteria like Thiobacillus spp. oxidize H2S to sulfate, reducing its concentration.

- Volatile organic acids are typically broken down through aerobic microbial activity, producing carbon dioxide and water.

- Maintaining optimal moisture levels and providing essential nutrients (nitrogen, phosphorus, etc.) is crucial for microbial activity.

- Moisture is often controlled to prevent over-wetting or drying out of the biofilter bed.

- pH levels in the biofilter are monitored and controlled to ensure an environment conducive to microbial activity.

- Some microorganisms may require specific pH conditions for efficient degradation.

- If you are treating both organic acid and H2S, greater care in maintaining pH in target ranges as SOX cultures tend to lower pH to ranges below ideal VOC culture growth.

- Regular monitoring of the biofilter's performance includes measuring inlet and outlet concentrations of odorous compounds.

- Adjustments to operating parameters, such as airflow rate, temperature, and nutrient supplementation, may be made based on monitoring results.

- Periodic maintenance involves replacing or replenishing the biofilter media and optimizing microbial populations.

- This ensures the long-term effectiveness of the biofilter.

- Treated air exiting the biofilter should meet regulatory standards for odor control.

- The treated air can be discharged into the atmosphere, and in some cases, it may undergo additional polishing treatments if needed.

Biofilter systems are often chosen for their sustainability, cost-effectiveness, and ability to handle a wide range of odorous compounds. However, the efficiency of biofilter treatment can be influenced by factors such as temperature, pH, nutrient availability, and the specific characteristics of the odorous compounds being treated. Regular monitoring and proper maintenance are essential for optimal performance.

RSS Feed

RSS Feed