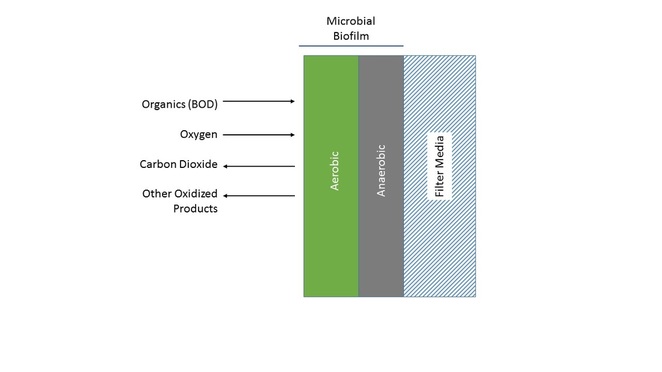

All fixed film system rely on a "host" surface for a microbial colony that forms a biofilm. The standard film is represented in the graph below and is found in all variations of fixed film systems.

I am going to do a series of posts on each of the fixed film system technologies with the goal being to give a general overview of the technology and most importantly the pros and cons of each. Today I am going to start with the oldest of the fixed film technologies - the trickling filter.

Trickling Filters

The oldest of the fixed film system is the trickling filter. The most basic systems spray influent over rocks or other media contained in a tower. Treatment capacity and efficiency can be mproved by adding blowers to provide additional oxygen to the lower levels of the tower. Existing trickling filters can also be improved by utilizing newer, higher surface area plastic media rather than rock or other traditional media. Other mostly industrial trickling filters, recycle biologial solids from the secondary clarifier to "re-seed" biomass to the front of the system.

- Simple, durable system

- Good efficiency at BOD and Ammonia removal

- Low power use

- Limited flexibility

- Not well buffered for shock loadings or spills

- Plugging or clogging of media

- Potential media fouling by substances such as oils & grease

- Odors

- Nuisance flies

Expected Treatment Efficiency

Loading (kg BOD/100 m3/day) BOD Removal %

Low Rate Filters 40 80 - 90%

Intermediate Rate 64 65 - 85%

High Rate 160 50 - 75%

Roughing Filters 480 40 - 65%

RSS Feed

RSS Feed