Enter the membrane solids separation systems - the MBR utilizes a membrane that retains solids in the biological unit and allows water to pass through the membrane for effluent discharge. As pressure required to push water through the membrane increases, the system uses backflushing to clean the membrane. If backflushing does not improve pressure requirements, the membrane must be chemically cleaned and eventually will require replacement.

What causes permeability decline?

- Influent

- Hydrophobic compounds - i.e. Fats, Oils & Grease

- Colloids

- Particulates - both organic & inorganic

- Biological

- Extracellular polymer substances (EPS)

- Soluble mirobial products - some can impact membrane pores

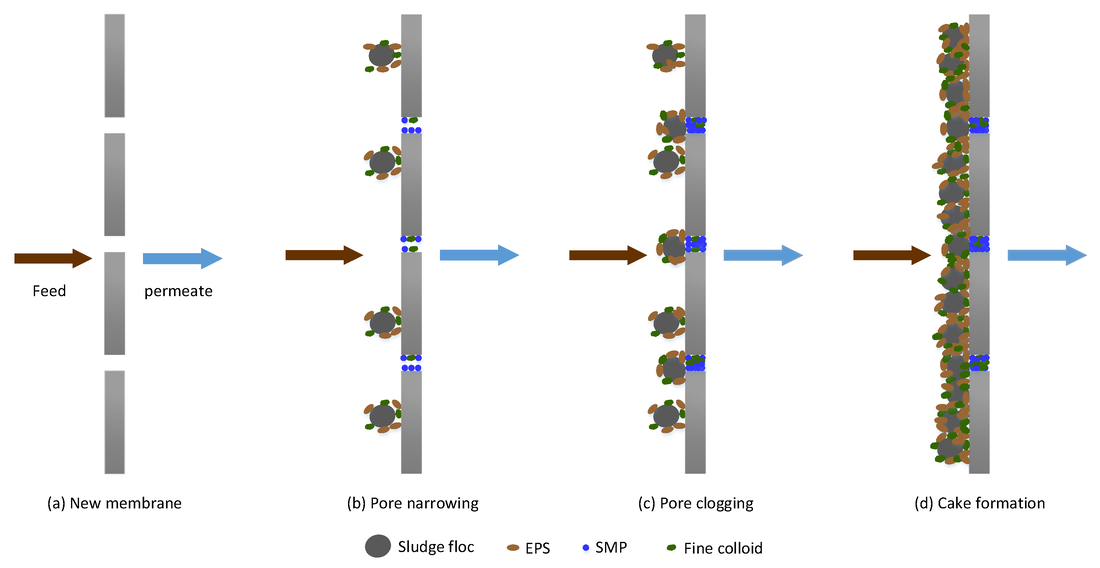

This brings us back to how filamentous and non-filamentous bulking organisms can impact the membrane. A non-ideal MLSS increases biological fouling potential. EPS in particular can foul the membrane by:

- Cake formation - common and cleaned during backflush

- Pore blocking - solids/eps impede water flow through pores

- Biofilm growth - EPS allows for biofilm attachment to membrane thereby blocking pores

If your biomass drifts to increased EPS (non-filamentous bulking, foaming filaments) and filaments that can stregthen biofilms on the membrane, then the membrane maintenance will include more cleaning cycles and earlier replacement than a system with better conditioned MLSS. Therefore, it is important to monitor EPS and filaments even with an MBR system.

A great short reivew of MBR fouling - https://www.mdpi.com/2077-0375/6/2/33/htm

RSS Feed

RSS Feed