The Moving Bed Biological Reactor (MBBR) is a fixed film system for waste treatment. It relies on microbial biofilms in a similar manner to trickling filters and RBCs but has been designed to address short-comings of the older systems.

The MBBR is simply a tank with high surface area plastic media that moves freely in the tank. Screens keep the media in the tank where it provides a surface for biofilm development. Compared to activated sludge units, the MBBR has the following advantages:

· Smaller foot print

· Lower cell yield (fewer solids to dewater)

· Useful for high rate industrial pretreatment

· A simple once through MBBR is easier to maintain & operate compared to most other systems

So we have a potential system that has low maintenance and operational costs like an older lagoon or pond system yet has the higher activity rates and smaller footprint of advanced treatment systems.

So what is the big advance in technology that makes MBBR possible? Well it was improved production of durable, high surface area plastic media – contrary to marketing documents most of the media has similar performance when you have equivalent surface area to volume. Everything else already existed for MBBR systems built from the ground up as an MBBR or a retrofit to an existing activated sludge tank.

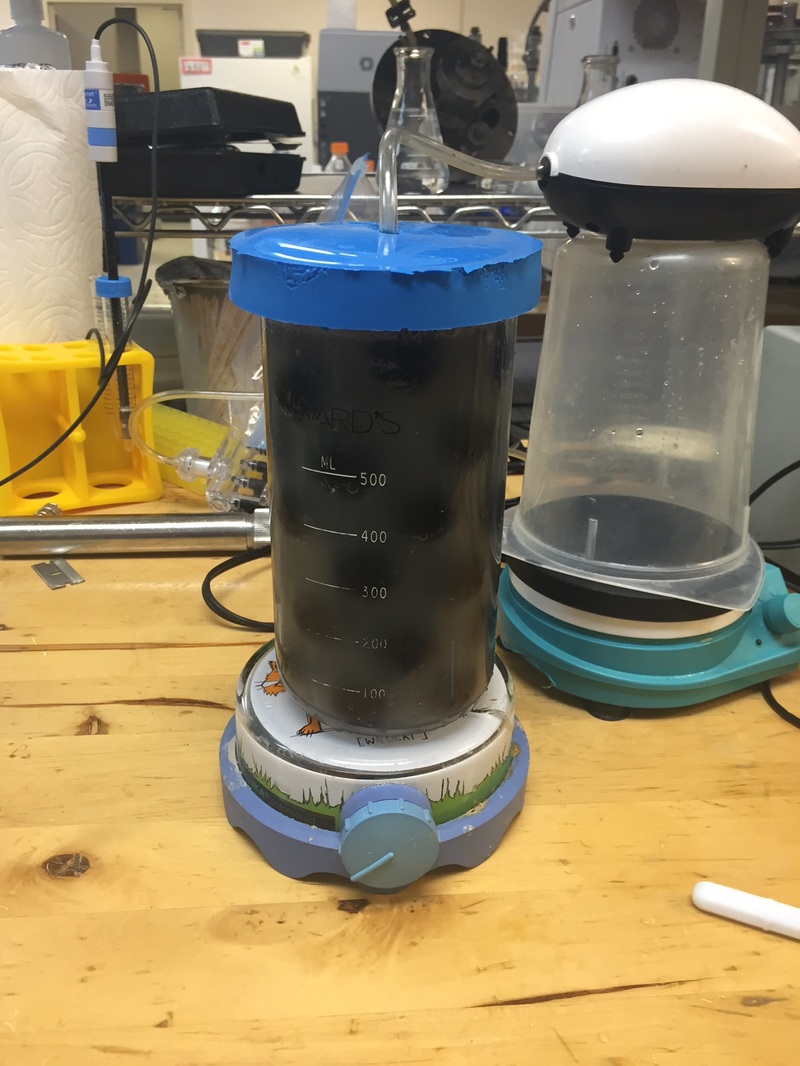

For the past two weeks, I have been evaluating the MBBR technology for industrial pretreatment of a high BOD5 waste stream that is discharged to a POTW. The goal is to reduce BOD5 from 4,700 mg/L to 500 mg/L in an effort to lower surcharges. The reason for MBBR selection is the need for concentrating a biomass for high BOD5 removal rates while also recognizing the facility does not want a complex wastewater system on-site. In lab testing, we are getting good results at loading rates of 5 – 7 kg BOD5 per cubic meter of media. In effect, we are building a “roughing” filter that is more resistant to fouling than older tricking filter systems. Below is the simple laboratory scale MBBR that I constructed for testing purposes.

RSS Feed

RSS Feed