- Remember "toxicity" is not a thing - you must identify what caused loss of biological activity and steps to prevent it in the future.

- Do not accept that "nothing changed" - something did change as evidenced by change in biomass activity.

- Look into influent and process flows - instead of running random outside lab tests, identify most likely candidates for upset. This is a thinking exercise - look at past events or operator notes.

- After identifying potential bad actors, you can start analytical testing. We have options tailored to specific industries. For example, Aster Bio uses a battery of petrochemical wastewater tests to identify levels of common bad actors in refinery wastewater. Using GC/MS and analytical tests, we can identify and quantify many "bad actors".

- Fixing the problem - since we cannot hold back water for extended periods, we usually use slowing forward flows, diversion of high strength wastes, additional oxygen, and bioaugmentation (or bugs). Note that the response includes multiple activities - this is where consultants can help bring new technologies or thought processes.

- After fixing and identifying the cause - develop monitoring and early warning abilities to meet the problem flows before acute toxicity. We can use many tools from step 5 above to prevent a major biological unit upset.

|

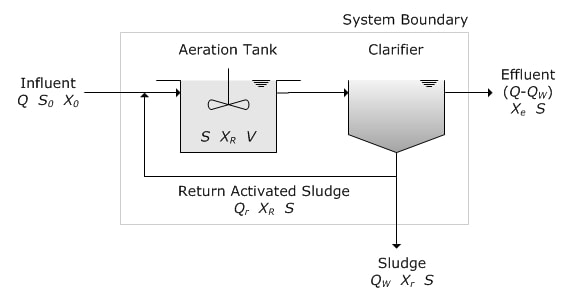

Many of us in industrial wastewater have experienced a toxic shock event. In most cases, toxic shock is noted by loss of nitrification and deflocculation (turbidity/floating solids). Today, I will work thorough my process for identifying what caused or is causing the upset.

Comments are closed.

|

AuthorErik Rumbaugh has been involved in biological waste treatment for over 20 years. He has worked with industrial and municipal wastewater facilities to ensure optimal performance of their treatment systems. He is a founder of Aster Bio (www.asterbio.com) specializing in biological waste treatment. Click to set custom HTML

Archives

April 2024

|

RSS Feed

RSS Feed