To remove both nitrate and nitrite from the water - thereby lowering total nitrogen discharge - a second anoxic (negative redox conditions) step with soluble organics present is required. Some early systems used added methanol and anoxic conditions to trigger bacteria into using nitrate/nitrite as an alternative to oxygen. More modern systems, have an anoxic stage where high soluble BOD influent and return MLSS (RAS) high in nitrate/nitrite mix. No matter which process is used, the anoxic conditions favor bacteria that can utilize nitrate and nitrite as an alternative electron acceptor when degrading soluble organics (BOD).

Using the nitrate/nitrite in this manner produces di-nitrogen (N2) gas (and some more problematic NO gas). The N2 gas production is inside the floc - extracellular polymers and floc surface temporarily trap the small nitrogen bubbles. The gas acts to float the MLSS. Once floated, the nitrogen bubbles slowly emerge from the floc and the MLSS settles.

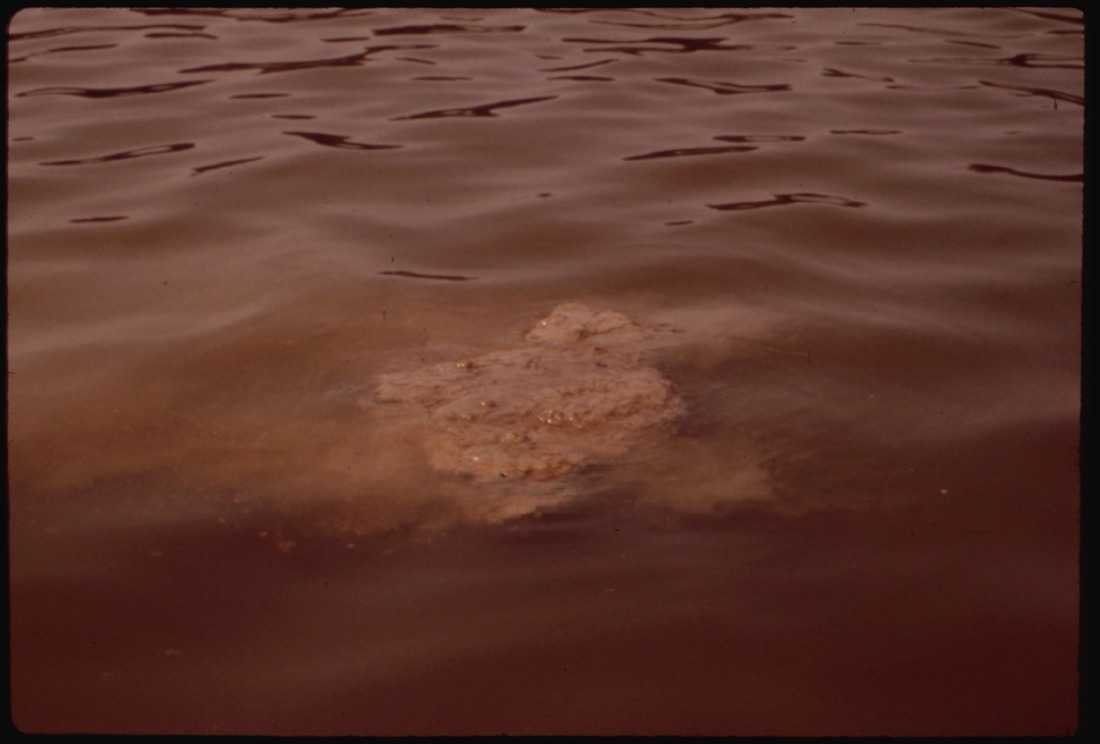

Problems happen when denitrification occurs in secondary clarifiers causing floating sludge and TSS carryover to the effluent. Normally we can control secondary clarifier denitrification by increasing return rates (lowering residence time of the clarifier beds). Other control options include water spay and higher rake speeds to help the nitrogen bubbles escape the floc. Denitrification can also increase effluent TSS in polishing ponds and storm water ponds in cases where you have biological floc, nitrate/nitrite, and soluble organics (this can even be from biological solids decomposing in warm temperatures).

RSS Feed

RSS Feed